HTU Face-Mount Truss Hanger

Product Details

The HTU face-mount truss hanger has nail patterns designed specifically for shallow heel heights, so that full allowable loads (with minimum nailing) apply to heel heights as low as 3 7/8". Minimum and maximum nailing options provide solutions for varying heel heights and end conditions.

Alternate allowable loads are provided for gaps between the end of the truss and the carrying member up to 1/2" max. to allow for greater construction tolerances (maximum gap for standard allowable loads is 1/8" per ASTM D7147). See technical bulletin Allowable Loads for Hangers with Gaps (T-C-HANGERGAP) for more information.

Material

- 16 gauge

Finish

- Galvanized

Installation

- Use all specified fasteners; see General Notes

- Can be installed filling round holes only, or filling round and triangle holes for maximum values

- See alternate installations in tables below

Options

- HTU may be skewed up to 67 1/2°. See table below.

- See engineering letter HTU with SD Screws (L-C-HTUSD) for installation with Strong-Drive® SD fasteners.

Related Literature

Product Information Table

| Model No. | Joist Size | Ga. | W (in.) | H (in.) | B (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|---|---|---|

| HTU210 | 2x10 | 16 | 1 5/8 | 9 1/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

| HTU210-2 | Double 2x10 | 16 | 3 5/16 | 9 1/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

| HTU26 | 2x6 | 16 | 1 5/8 | 5 7/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

| HTU26-2 | Double 2x6 | 16 | 3 5/16 | 5 7/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

| HTU28 | 2x8 | 16 | 1 5/8 | 7 1/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

| HTU28-2 | Double 2x8 | 16 | 3 5/16 | 7 1/16 | 3 1/2 | Zinc Galvanized, G90 | 1 |

Load Tables

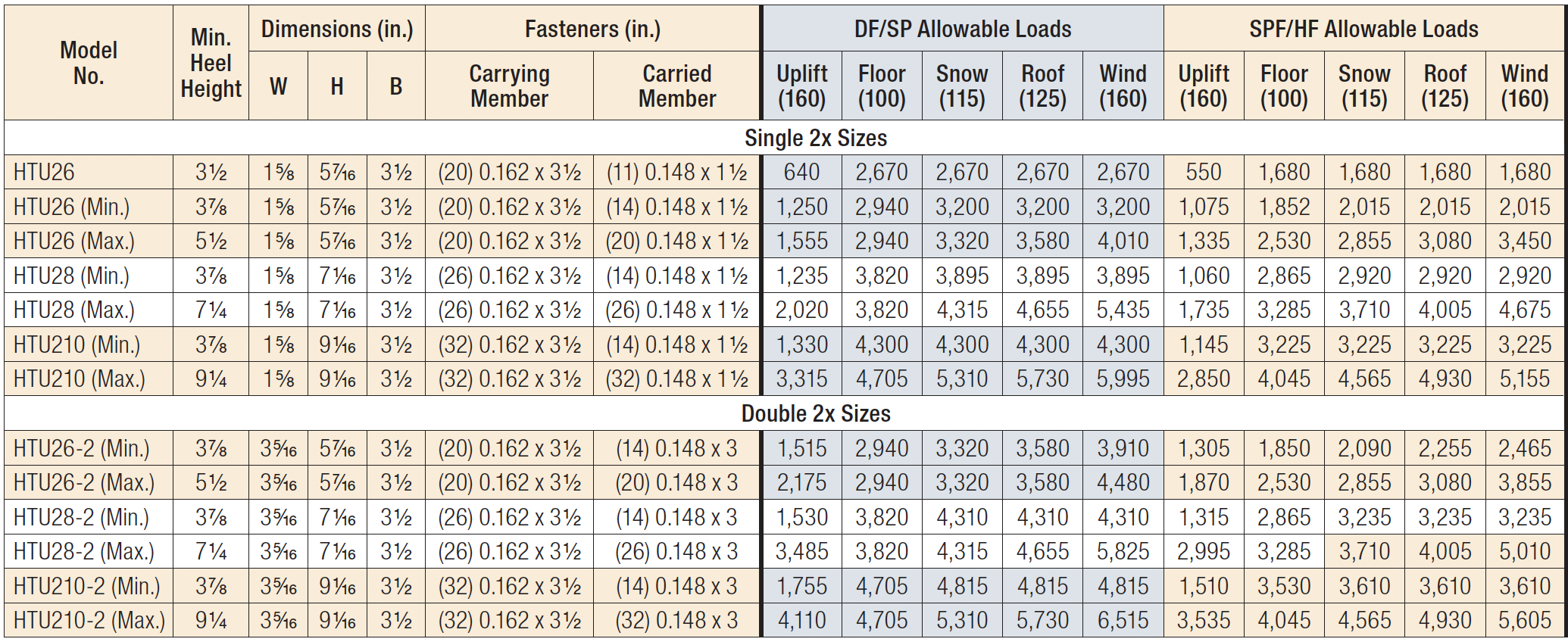

Standard Allowable Loads (1/8" Maximum Hanger Gap)

Many of these products are approved for installation with Strong-Drive® SD Connector screws.

- The maximum hanger gap is measured between the joist (or truss) end and the carrying member.

- Minimum heel heights required for full table loads are based on a minimum 2:12 pitch.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Wind (160) is a download rating.

- For hanger gaps between 1/8" and 1/2", use the Alternate Allowable Loads.

- Truss chord cross-grain tension may limit allowable loads in accordance with ANSI/TPI 1-2014. Simpson Strong-Tie® Connector Selector™ software includes the evaluation of cross-grain tension in its hanger allowable loads. For additional information, contact Simpson Strong-Tie.

- Loads shown are based on a minimum two-ply 2x carrying member. For single 2x carrying members, use 0.148" x 1 1/2" nails in the header and reduce the allowable download to 0.70 of the table value. The allowable uplift is 100% of the table load.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

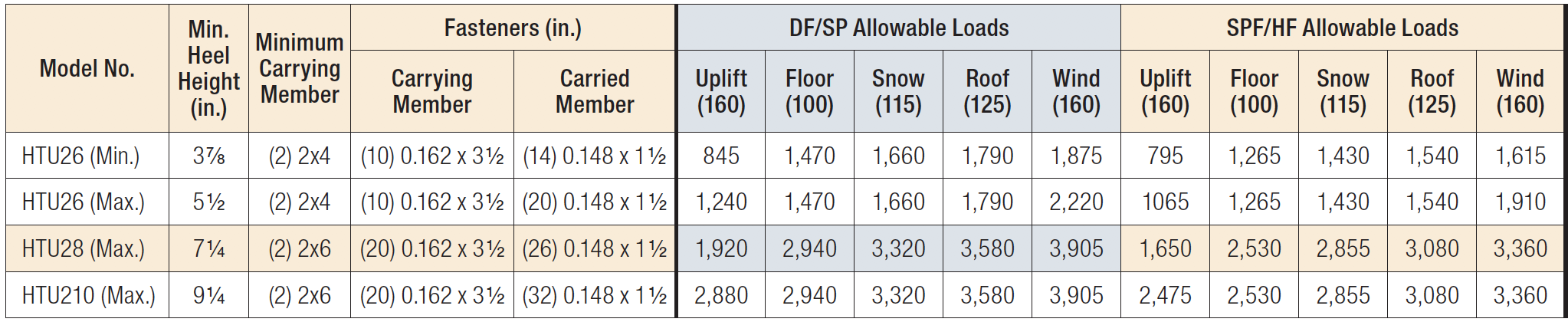

Alternate Installation Table for 2x4 and 2x6 Carrying Member

Many of these products are approved for installation with Strong-Drive® SD Connector screws.

- See table above for dimensions and additional footnotes.

- Maximum hanger gap for the alternative installation is 1/2".

- Wind (160) is a download rating.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

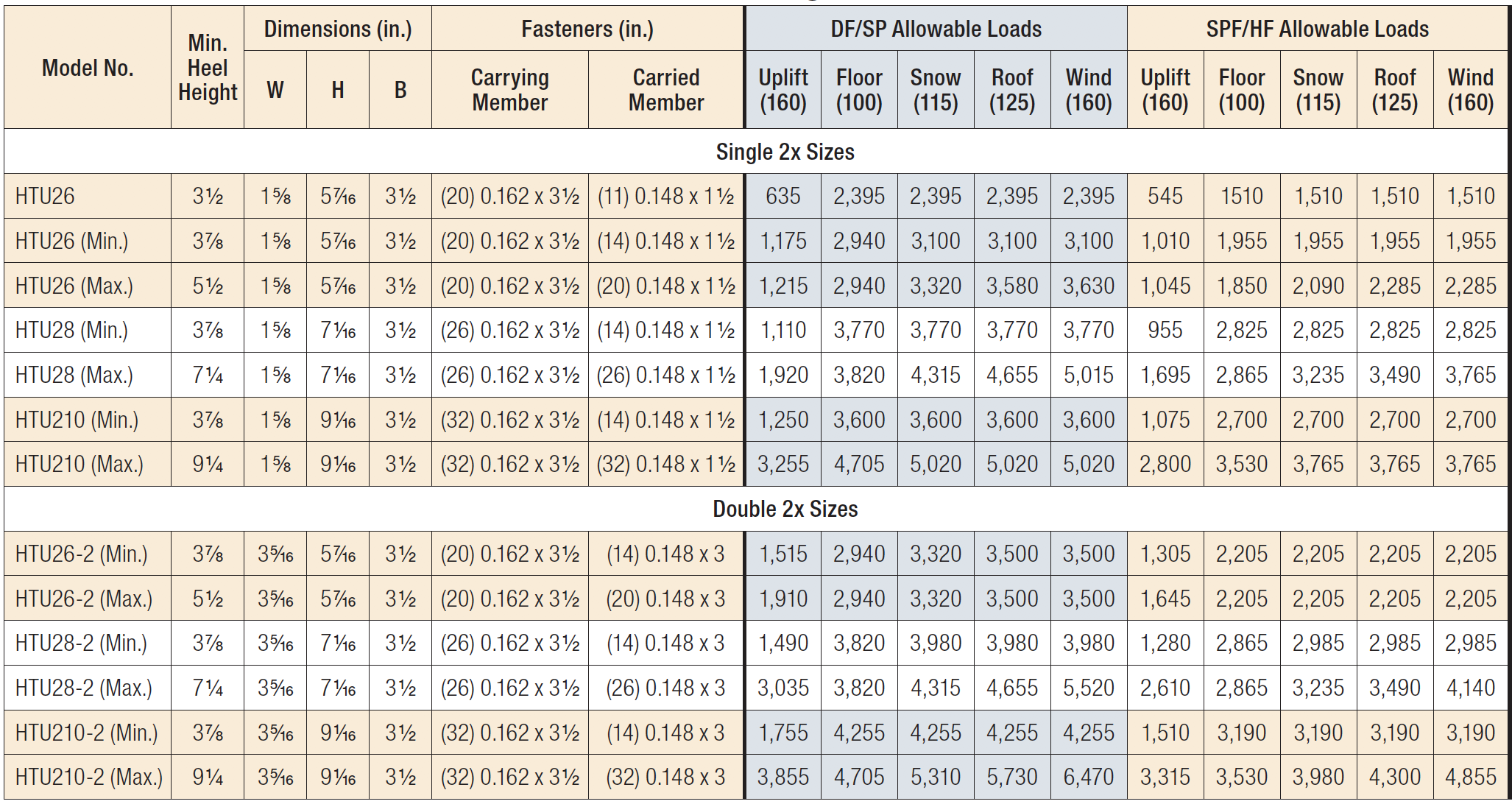

Alternate Allowable Loads (1/2" Maximum Hanger Gap)

- The maximum hanger gap is measured between the joist (or truss) end and the carrying member.

- Minimum heel heights required for full table loads are based on a minimum 2:12 pitch.

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Wind (160) is a download rating.

- For hanger gaps between 1/8" and 1/2", use the Alternative Allowable Loads.

- Truss chord cross-grain tension may limit allowable loads in accordance with ANSI/TPI 1-2014. Simpson Strong-Tie® Connector Selector® software includes the evaluation of cross-grain tension in its hanger allowable loads. For additional information, contact Simpson Strong-Tie.

- Loads shown are based on a minimum two-ply 2x carrying member. For single 2x carrying members, use 0.148" x 1 1/2" nails in the header and reduce the allowable download to 0.70 of the table value. The allowable uplift is 100% of the table load.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

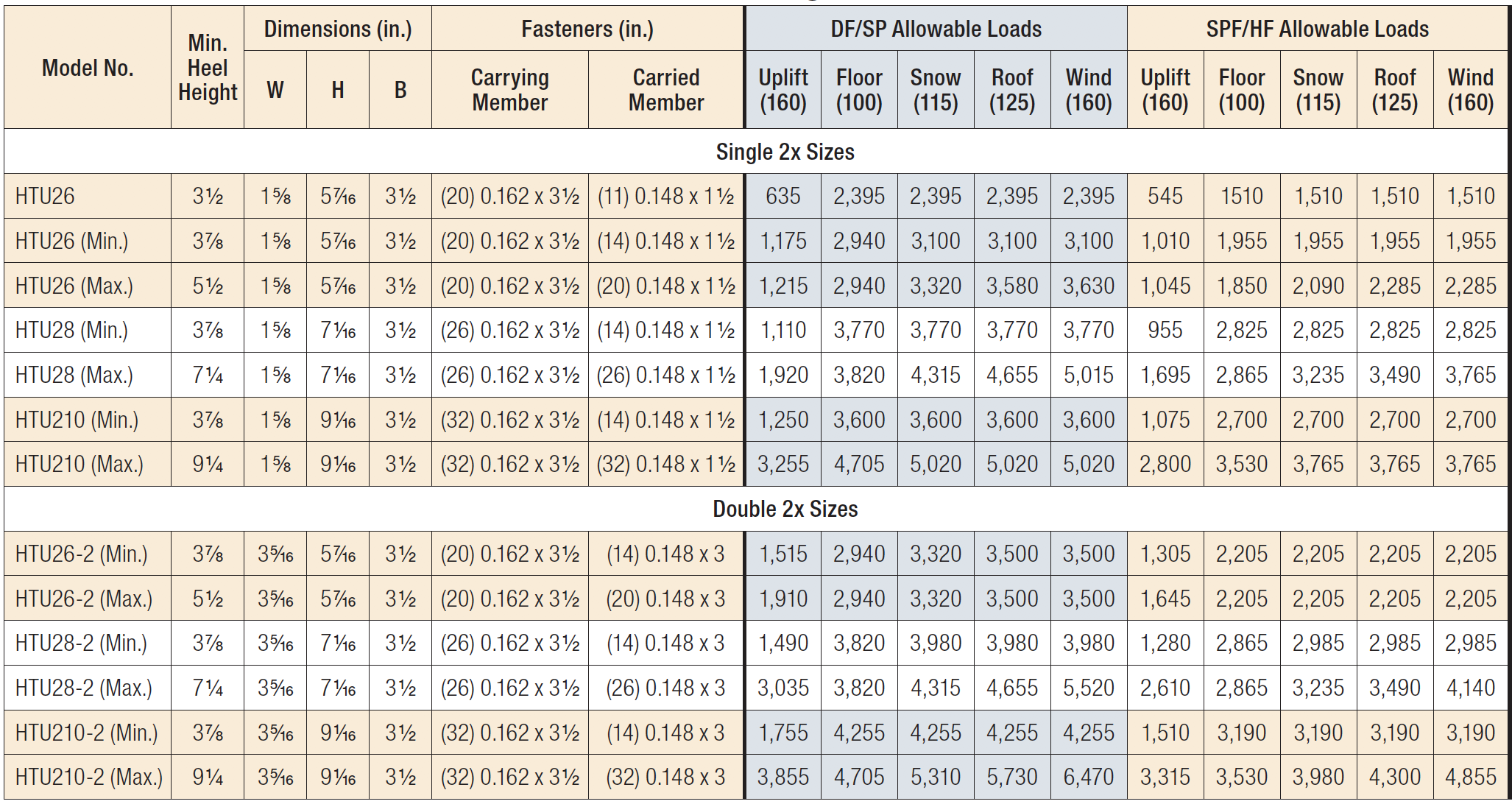

Allowable Loads for Skewed HTU Hangers

- Uplift loads have been increased for earthquake or wind loading with no further increase allowed. Reduce where other loads govern.

- Allowable downloads may not be increased.

- Maximum hanger gap between end of joist (truss) and face of carrying member is 1/8".

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|