Strong-Drive® Self-Drilling X Metal Screw

Product Details

Key Features

- 5/16" hex head (replacement driver bit — BITHEXR516-R1)

- Drill point

- Hex-washer head

Applications

- Steel decking to structural steel

- Steel stitching (“side-lap” stitching)

- Cold-formed steel framing

Warning

- Industry studies show that hardened fasteners can experience performance problems in wet or corrosive environments. Accordingly, use this product in dry, interior, and noncorrosive environments only.

Related Links

- Fastening Systems Technical and Installation Notes

- Self-Drilling X Metal Screw also available collated for the Quik Drive® system

The Steel Deck Institute updated the 4th Edition of the Diaphragm Design Manual (SDI-DDM04) to include Simpson Strong-Tie as an approved manufacturer of screws used for steel decking.

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), page 113

- Fastener Technical Data and Loads: C-F-2023TECHSUP, pages 228–229

Related Literature

Product Information Table

| Model No. | Coating/Material | Screw Size | Length (in.) | Head Diameter (in.) | Drive Type | Head Type | Thread Type | TPI | Max. Grip Length (in.) | Point Type | Point Size | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XQ1B1016-4K | Quik Guard® Coating | #10 | 1 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 16 | 0.469 | Drill Point | 3 | 4000 |

| XQ1B1214-3.5K | Quik Guard® Coating | #12 | 1 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 14 | 0.402 | Drill Point | 3 | 3500 |

| X1B1016-4K | Clear Zinc Coating | #10 | 1 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 16 | 0.469 | Drill Point | 3 | 4000 |

| X1B1214-3.5K | Clear Zinc Coating | #12 | 1 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 14 | 0.402 | Drill Point | 3 | 3500 |

| X34B1016-5K | Clear Zinc Coating | #10 | 3/4 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 16 | 0.233 | Drill Point | 3 | 5000 |

| XU34B1016-5K | Clear Zinc Coating | #10 | 3/4 | 0.420 | 5/16 in. Hex | Hex Washer Head | Machine Threads | 16 | 0.333 | Drill Point | 1 | 5000 |

Product Information Table

| Model No. | Length (in.) | Screw Size | Drive Type | Head Diameter (in.) | Head Type | Thread Type | TPI | Point Size | Point Type | Coating/Material | Packaging Quantity | UPC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XQ112B1224-2K | 1 1/2 | #12 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 24 | 5 | Drill Point | Quik Guard® Coating | 2000 | 746056456803 |

| XQ114B1224-2.5K | 1 1/4 | #12 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 24 | 5 | Drill Point | Quik Guard® Coating | 2500 | |

| XQ1B1016-4K | 1 | #10 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 16 | 3 | Drill Point | Quik Guard® Coating | 4000 | |

| XQ1B1214-3.5K | 1 | #12 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 14 | 3 | Drill Point | Quik Guard® Coating | 3500 | |

| X114B1224-2.5K | 1 1/4 | #12 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 24 | 5 | Drill Point | Clear-Zinc Coating | 2500 | 707392884873 |

| X1B1016-4K | 1 | #10 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 16 | 3 | Drill Point | Clear-Zinc Coating | 4000 | 746056005407 |

| X1B1214-3.5K | 1 | #12 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 14 | 3 | Drill Point | Clear-Zinc Coating | 3500 | 746056005421 |

| X34B1016-5K | 3/4 | #10 | 5/16 in. Hex | 0.415 | Hex Washer Head | Machine Threads | 16 | 3 | Drill Point | Clear-Zinc Coating | 5000 | |

| XU34B1016-5K | 3/4 | #10 | 5/16 in. Hex | 0.475 | Hex Washer Head | Machine Threads | 16 | 1 | Drill Point | Clear-Zinc Coating | 5000 | |

| These coated fasteners possess a level of corrosion resistance that makes them suitable for use in some exterior and corrosive environments and with some preservative-treated woods. For applications in higher-exposure applications, consider type-300 series stainless-steel fasteners for superior corrosion resistance. See additional important information before selecting a fastener for a specific application. | ||||||||||||

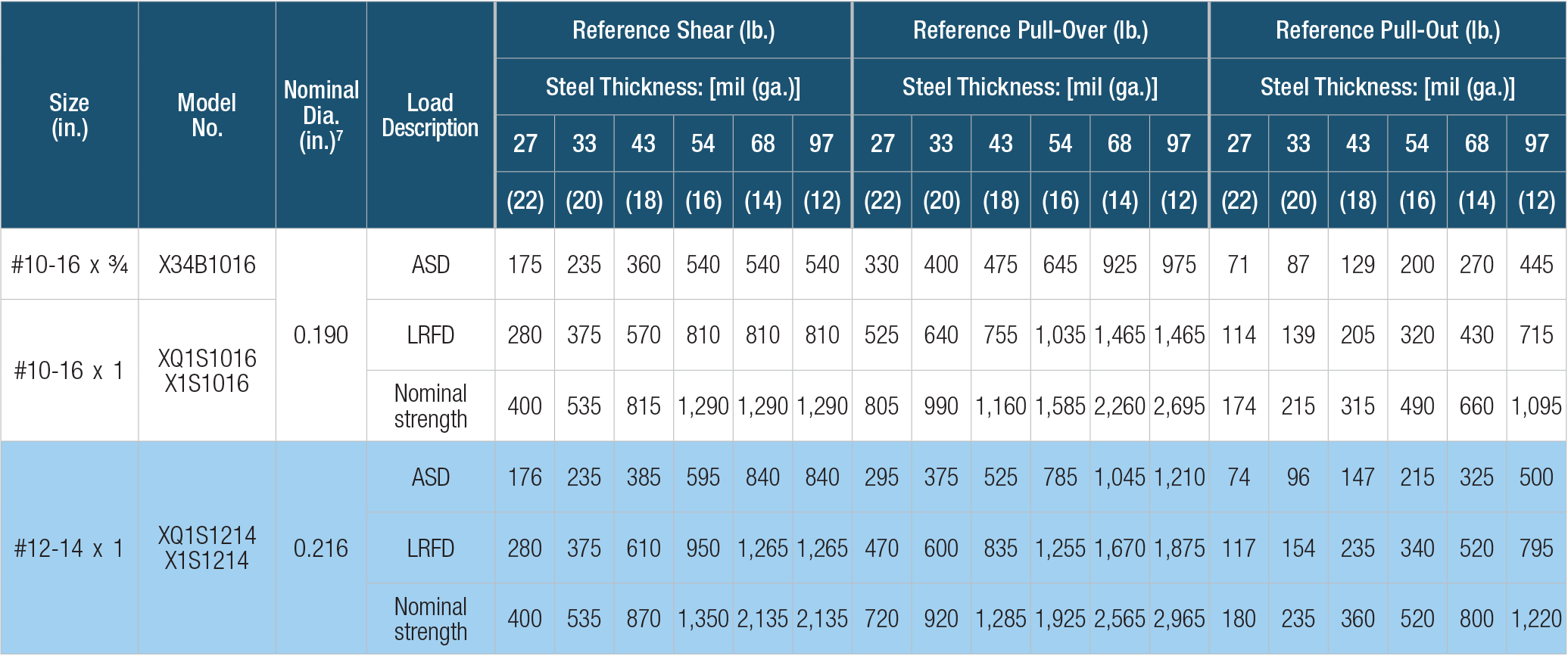

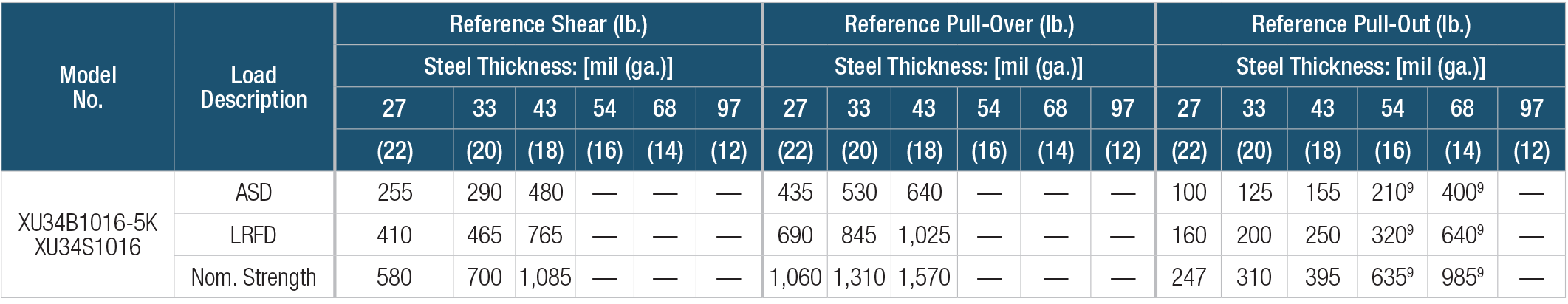

Load Tables

X Metal Screw — Cold-Formed Steel Connection Loads

- Screws and screw connections have been tested per AISI Standard Test Method S904 and S905 with the exception of 22-gauge values which are based on calculations of the AISI S100.

- The tabulated ASD and LRFD allowable loads for cold-formed steel (CFS) members are based on the lower of the screw strength or the strength of the screw in the connected members per AISI S100.

- The safety factor Ω and resistance factor Φ used to determine the ASD and LRFD strength are based on AISI S100.

- The nominal strength values listed are achieved under laboratory conditions and should not be used for design loads.

- Values are based on CFS members with a minimum yield strength of Fy = 33 ksi and tensile strength of Fu = 45 ksi for 43 mil (18 ga.) to 27 mil (22 ga.), minimum yield strength of Fy = 50 ksi and Fu = 65 ksi for 54 mil (16 ga.) to 97 mil (12 ga.), and a minimum yield strength of Fy = 36 ksi and Fu = 58 ksi for 1/8" and thicker.

- For design purposes, steel-sheet thicknesses are 0.0283" for 27 mil, 0.0346" for 33 mil, 0.0451" for 43 mil, 0.0566" for 54 mil, 0.0713" for 68 mil, and 0.1017" for 97 mil. The actual sheet thickness shall not be less than 95% of these design thicknesses as specified in AISI S100.

- Screw diameters per AISI S200 General Provisions Commentary Table D1-1.

- Minimum required screw length is the lesser of 3/4" or the minimum length required for the screw to extend through the steel connection a minimum of three exposed threads per 2004 AISI General Provisions Standard section D1.3.

- Screw head or washer diameter, dw, for #10 and #12 screws is 0.398".

- The allowable load (ASD) values showing are not permitted to be increased for short duration loads such as wind or earthquake loads.

- The lower of the pull-over and pull-out allowable load should be used for tension design.

- The tabulated shear values are based on the thinner steel member in connection. Steel thickness for both members must be in the range of 1/2"–22 gauge.

- The XQ-S1224 screws are recommended for 16 gauge and thicker steel.

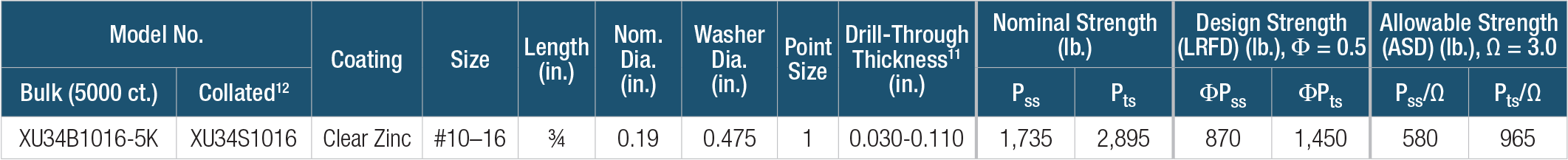

Screw Properties and Strengths

Cold-Formed Steel Connection Loads

- Pss is the nominal shear strength of the screw and Pts is the nominal tensile strength of the screw.

- The safety factor Ω and resistance factor Φ are calculated based on AISI S100-07 Chapter F for tested connections.

- The nominal strength values listed are achieved under laboratory conditions and should not be used for design loads.

- Values are based on CFS members with a minimum yield strength of Fy = 33 ksi and tensile strength of Fu = 45 ksi for 43 mil (18 ga.) to 27 mil (22 ga.) and minimum yield strength of Fy = 50 ksi and Fu = 65 ksi for 54 mil (16 ga.) to 97 mil (12 ga.).

- For design purposes, steel sheet thicknesses are 0.0283" for 27 mil, 0.0346" for 33 mil, 0.0451" for 43 mil, 0.0566" for 54 mil, 0.0713" for 68 mil, and 0.1017" for 97 mil. The actual sheet thickness shall not be less than 95% of these design thicknesses as specified in AISI S100-07 Section A2.4.

- Screws must extend through the steel connection a minimum of 3 exposed threads per AISI General Provisions Standard Section D1.3.

- The lower of the pull-over and pull-out load should be used for tension design.

- The tabulated values are based on the thinner steel member in the connection.

- Pull-Out values for the XU34B1016 and XU34S1016 with 54 mil and 68 mil steel thicknesses are provided for conditions in which the member in contact with the screw head is thinner than the 54 or 68 mil base material and the total material thickness is less than the 0.110". Use the thickness of the member in contact with the screw head to determine Pull-Over value and the base member thickness (member not in contact with screw head) to determine the Pull-Out value.

- The allowable load (ASD) values shown are not permitted to be increased for short-duration loads such as wind or earthquake loads.

- Drill-through thickness is the recommended minimum and maximum thickness of the total assembly. This includes thickness of all the members, including the gaps between them.

- Collated screw models are designed for use with the Quik Drive® system.

See additional Load Tables, Technical Data and Installation Instructions for the Strong-Drive® Self-Drilling X Metal screw

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|