TJC Jack Truss Connector

Face-Mount Hangers for Plated Truss

This product's information may differ depending on the category of use. You are currently viewing details related to Face-Mount Hangers for Plated Truss. You can also view product information related to the category: Roof Truss and Rafter Connectors, Ties, and Straps for Cold-Formed Steel Construction

Product Details

TJC is a versatile connector for jack trusses. Adjustable from 0° to 85° (shipped with 67.5° bend). Nail hole locations allow for easy installation. Minimum nailing option on TJC37 provides faster installation and lower installed cost.

Material

- 16 ga. (54 mil)

Finish

- Galvanized (G90)

Installation

- Use all specified fasteners; see General Notes.

- TJC37 can be installed filling round holes only, or filling round and triangle holes for maximum values.

- To reduce the potential for splitting, install the TJC with a minimum 3/16" edge distance on the chord members.

- Position the jack truss on the inside of the bend line with the end of the jack truss flush with the bend line.

- Bend the TJC to the desired position (one bend cycle only).

- No bevel cut required.

- Attachment of TJC to the top chord requires the designer to check connection geometry for placement on both carried and carrying chord members. See Top Chord Member Sizes table for suggested chord sizes.

- Supported jack member is a single 2x.

Related Literature

Product Information Table

| Model No. | Ga. | W (in.) | H (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|---|

| TJC37 | 16 | 7 | 3 1/8 | Zinc Galvanized, G90 | 1 |

| TJC57 | 16 | 7 | 5 1/8 | Zinc Galvanized, G90 | 1 |

Product Information Tables

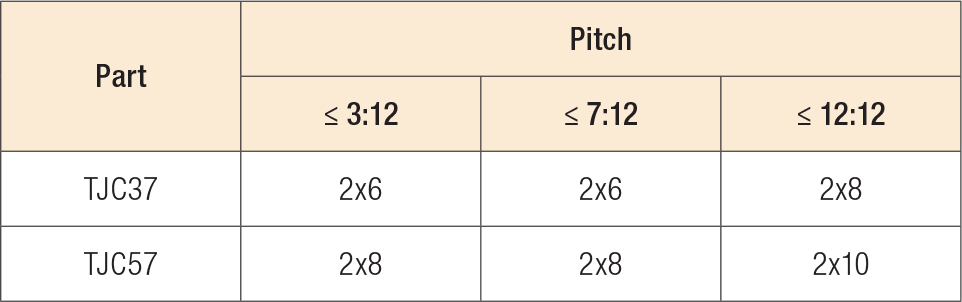

Top Chord Member Sizes

Load Tables

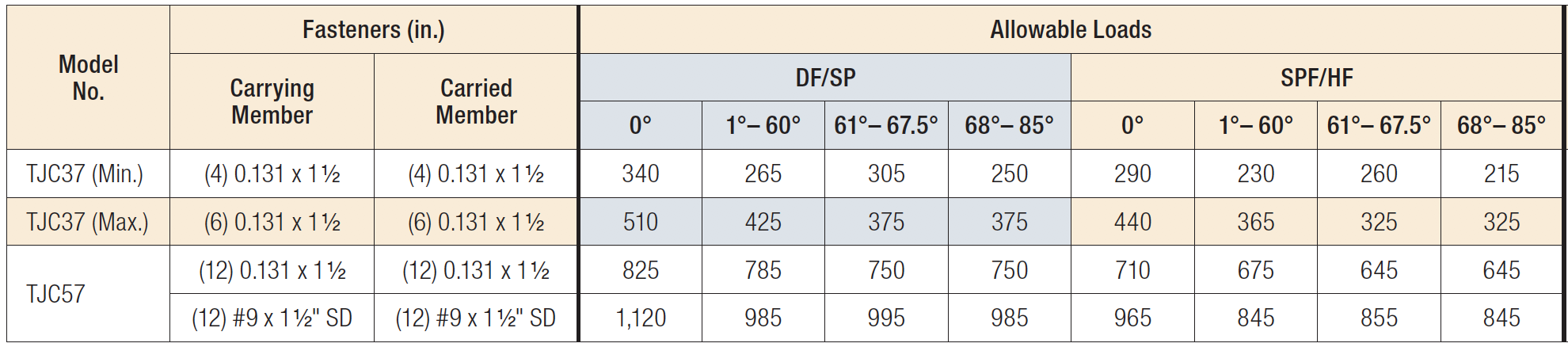

Standard Installation

See footnotes below.

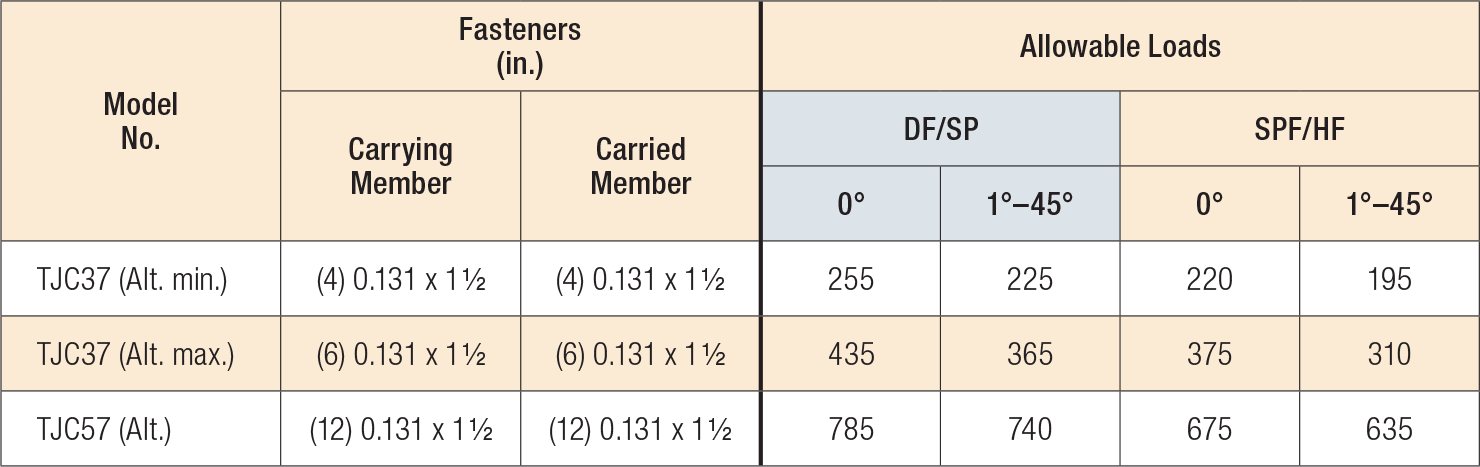

Alternate Installation

- Loads may not be increased for duration of load.

- Allowable loads are for upward or downward direction.

- TJC37 and TJC57 require single-ply carried members with minimum 2x4 and 2x6 chord members, respectively.

- For back-to-back installation on a single-ply girder/hip member, use a 0.70 reduction of table loads.

- Fasteners: Nail dimensions in the table are listed diameter by length. For additional information, see Fastener Types and Sizes Specified for Simpson Strong-Tie Connectors.

- Fasteners: SD screws are Simpson Strong-Tie® Strong-Drive® screws. See fastener information.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|