Strong-Drive® SDW™ TRUSS-PLY Screw

Strong-Drive® Interior Wood Screws

This product's information may differ depending on the category of use. You are currently viewing details related to Strong-Drive® Interior Wood Screws. You can also view product information related to the category: Fasteners for the Timber Drive™ System

Product Details

The Strong-Drive SDW Truss-Ply screw is a high-strength structural wood screw specifically designed for fastening multi-ply wood members, such as joining plated trusses and solid-sawn lumber. The SDW installs easily with no predrilling and is available in optimized lengths for fastening 2-, 3- and 4-ply trusses. With the SDW Truss-Ply screw, multi-ply trusses and components can be fastened from one side without requiring the lifting and flipping of heavy assemblies. It is code listed in IAPMO UES ER-192 and meets 2018 and 2021 IRC® and IBC® code requirements for most common wood framing applications with wood and engineered wood.

Key Features

- Large washer head with nibs provides maximum bearing area; stamped with the Simpson Strong-Tie “≠” sign and fastener length for easy identification after installation

- 6-lobe, T40 drive provides positive engagement that makes the screw easy to drive and improves bit life (replacement driver bit — BIT40T-134-R2)

- Low-profile head results in less interference after installation; makes stacking and sliding members easier and allows installation of hardware and finishes to be virtually flush

- Higher shear values than competitive products enable wider spacing, saving time and money

- Bold thread design provides superior holding power and cinches fastened members together for consistent installation

- SawTooth® point ensures fast starts, reduces installation torque and eliminates the need for predrilling in most applications

- Retail and mini-bulk packs include one 6-lobe, T40 driver bit; bulk packs include two driver bits

Applications

- Truss-ply fastening

Patent Information

- US Patents 9,523,383; 11,181,138

Related Links

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), page 101

- Fastener Technical Data and Loads: C-F-2023TECHSUP, pages 125–130 and 132–133

Related Literature

Product Information Table

| Model No. | Coating/Material | Length (in.) | Head Diameter (in.) | Shank Diameter (in.) | Drive Type | Head Type | Thread Length (in.) | Point Type | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|---|

|

Footnotes

|

|||||||||

| SDW22300 | E-coat® Electrocoating | 3 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 950 |

| SDW22300MB | E-coat® Electrocoating | 3 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 250 |

| SDW22300-R50 | E-coat® Electrocoating | 3 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 50 |

| SDW22438 | E-coat® Electrocoating | 4 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 600 |

| SDW22438MB | E-coat® Electrocoating | 4 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 200 |

| SDW22438-R50 | E-coat® Electrocoating | 4 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 50 |

| SDW22458 | E-coat® Electrocoating | 4 5/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 600 |

| SDW22458MB | E-coat® Electrocoating | 4 5/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 200 |

| SDW22458-R50 | E-coat® Electrocoating | 4 5/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 50 |

| SDW22600 | E-coat® Electrocoating | 6 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 500 |

| SDW22600MB | E-coat® Electrocoating | 6 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 200 |

| SDW22600-R50 | E-coat® Electrocoating | 6 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 50 |

| SDW22638 | E-coat® Electrocoating | 6 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 500 |

| SDW22638MB | E-coat® Electrocoating | 6 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 200 |

| SDW22638-R50 | E-coat® Electrocoating | 6 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 3/8 | SawTooth® Point | 50 |

Product Information Table

| Model No. | Length (in.) | Drive Type | Head Type | Thread Length | Shank Diameter (in.) | Coating/Material | Packaging Quantity | UPC |

|---|---|---|---|---|---|---|---|---|

| SDW22300 | 2 15/16 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 950 | 707392156406 |

| SDW22300MB | 2 15/16 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 250 | 707392125501 |

| SDW22300-R50 | 2 15/16 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392849605 |

| SDW22438 | 4 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 600 | 707392318804 |

| SDW22438MB | 4 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392770305 |

| SDW22438-R50 | 4 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392912804 |

| SDW22458 | 4 5/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 600 | 707392149408 |

| SDW22458MB | 4 5/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392706502 |

| SDW22458-R50 | 4 5/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392142706 |

| SDW22600 | 6 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 500 | 707392576303 |

| SDW22600MB | 6 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392999003 |

| SDW22600-R50 | 6 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392229100 |

| SDW22638 | 6 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 500 | 707392232506 |

| SDW22638MB | 6 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392990604 |

| SDW22638-R50 | 6 3/8 | T-40 6-Lobe | Low Profile Head | 1 7/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392414308 |

Load Tables

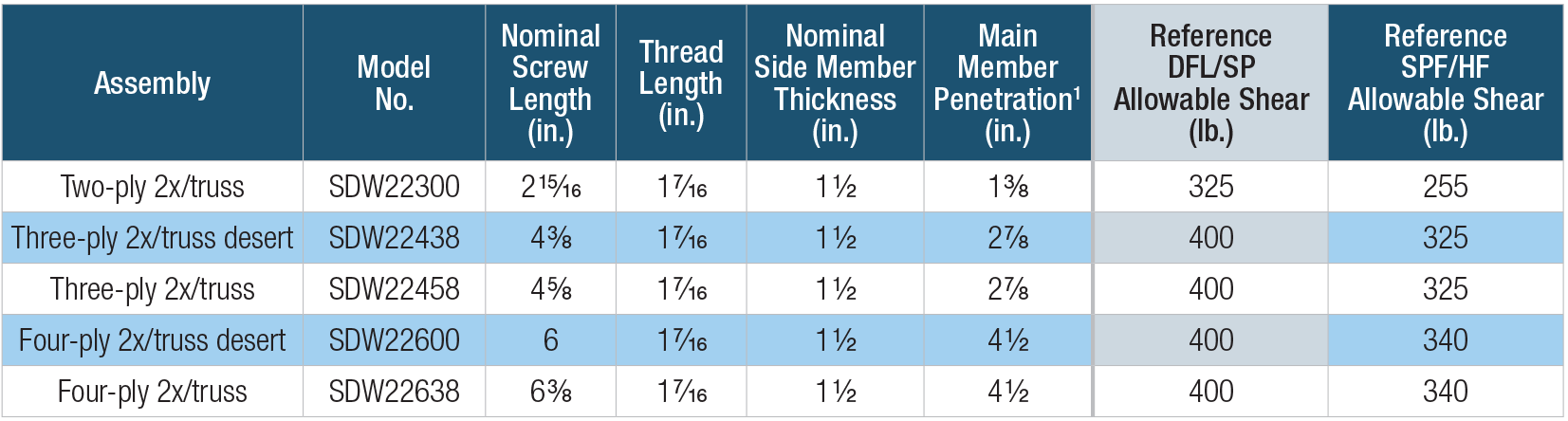

SDW TRUSS-PLY — Allowable Shear Loads — DFL, SP, SPF, HF Lumberand 2x Truss Loaded on Head Side

- For minimum penetration into main (outermost) member of 1 1/8", use 235 lb. for DFL/SP and 210 lb. for SPF/HF.

(Three-ply assembly shown — other configurations similar)

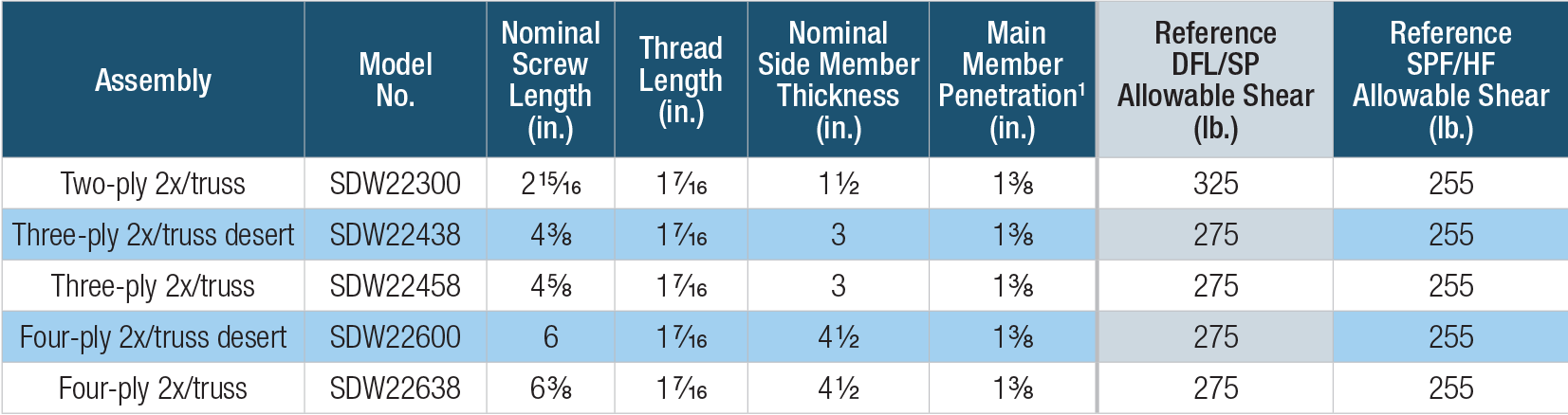

SDW TRUSS-PLY — Allowable Shear Loads — DFL, SP, SPF, HF Lumber and 2x Truss Loaded on Point Side

- For minimum penetration into main member of 1 1/8", use 235 lb. for DFL/SP and 210 lb. for SPF/HF.

(Three-ply assembly shown — other configurations similar)

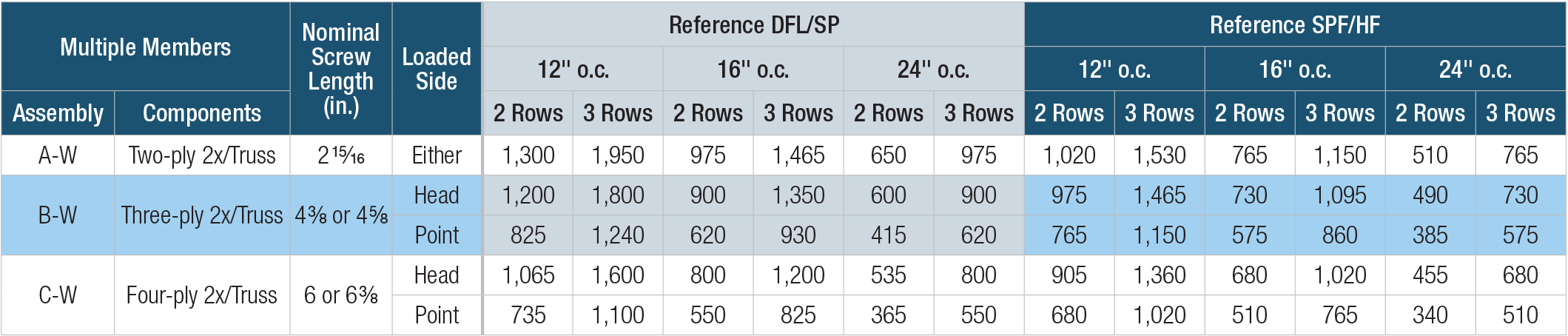

SDW TRUSS-PLY — Allowable Uniform Load (plf) Applied to Either Outside Member — Side-Loaded Multi-Ply Assemblies

- Each ply is assumed to carry same proportion of load.

- Loads may be applied to the head side and point side concurrently provided neither published allowable load is exceeded. (Example: a three-ply DFL assembly with a head side load of 1,300 plf and point side load of 900 plf may be fastened together with 3 rows of SDW at 16" o.c. between fasteners in a row.)

- When hangers are installed on point side, hanger face fasteners shall be a minimum of 3" long.

- Tables are based on Main Member Penetration as noted in tables above.

- Hanger load spacing on the multi-ply assembly should not exceed 24" o.c. Exception: On a skewed girder, hanger loads up to 34" o.c. (resulting from joists uniformly spaced up to 24" o.c.) may be converted to a uniform load.

See additional Load Tables, Technical Data and Installation Instructions for the Strong-Drive® SDW Truss-Ply screw.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|