Strong-Drive® SDCF TIMBER-CF Screw

Fasteners for the Timber Drive™ System

This product's information may differ depending on the category of use. You are currently viewing details related to Fasteners for the Timber Drive™ System. You can also view product information related to the category: Strong-Drive® Interior Wood Screws

Product Details

The Strong-Drive SDCF Timber-CF screw is a structural fastener available in a variety of lengths and is designed for cross-laminated timber construction, mass timber construction and general interior applications. These 0.315"- and 0.390"-diameter structural fasteners provide uncompromised strength for these demanding applications. The large flat head with underhead nibs provides for clean countersinking. The yellow zinc, fully-threaded screw with a proprietary point provides fast starts and excellent holding power.

Key Features

- Designed to be countersunk with head flush to wood surface

- Fully threaded to provide high withdrawal resistance

- Flat head with nibs helps countersink the screw for a flush finish

- Heavy-duty, fully-threaded shank provides strength, with superb withdrawal resistance

- Head stamp includes length in mm for inspection

- Interior grade yellow-zinc coating

- Deep 6-lobe recess for a secure drive (T40 - replacement bit part number BIT40T-134-R2; T50 - replacement bit part number BIT50T-2-R1.)

Applications

- Beam reinforcement, wall-to-wall, floor-to-floor, support beams, butt joints

Related Links

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), page 96

- Fastener Technical Data and Loads: C-F-2023TECHSUP, pages 140–144

Related Literature

Product Information Table

| Model No. | Coating/Material | Length (in.) | Head Diameter (in.) | Shank Diameter (in.) | Drive Type | Head Type | Thread Length (in.) | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|

| SDCF221014 | Yellow-Zinc Coated | 10 1/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 9 3/4 | 250 |

| SDCF221014-R50 | Yellow-Zinc Coated | 10 1/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 9 3/4 | 50 |

| SDCF221134 | Yellow-Zinc Coated | 11 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 11 3/8 | 250 |

| SDCF221134-R50 | Yellow-Zinc Coated | 11 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 11 3/8 | 50 |

| SDCF221334 | Yellow-Zinc Coated | 13 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 13 3/8 | 250 |

| SDCF221334-R50 | Yellow-Zinc Coated | 13 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 13 3/8 | 50 |

| SDCF22434 | Yellow-Zinc Coated | 4 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 4 1/4 | 250 |

| SDCF22434-R50 | Yellow-Zinc Coated | 4 3/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 4 1/4 | 50 |

| SDCF22512 | Yellow-Zinc Coated | 5 1/2 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 5 1/8 | 250 |

| SDCF22512-R50 | Yellow-Zinc Coated | 5 1/2 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 5 1/8 | 50 |

| SDCF22614 | Yellow-Zinc Coated | 6 1/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 5 7/8 | 250 |

| SDCF22614-R50 | Yellow-Zinc Coated | 6 1/4 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 5 7/8 | 50 |

| SDCF22700 | Yellow-Zinc Coated | 7 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 6 5/8 | 250 |

| SDCF22700-R50 | Yellow-Zinc Coated | 7 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 6 5/8 | 50 |

| SDCF22858 | Yellow-Zinc Coated | 8 5/8 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 8 1/4 | 250 |

| SDCF22858-R50 | Yellow-Zinc Coated | 8 5/8 | 0.590 | 0.230 | T40 6-Lobe | Flat Head with Nibs | 8 1/4 | 50 |

| SDCF271100 | Yellow-Zinc Coated | 11 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 10 3/4 | 150 |

| SDCF271100-R30 | Yellow-Zinc Coated | 11 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 10 3/4 | 30 |

| SDCF271958 | Yellow-Zinc Coated | 19 5/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 19 3/8 | 100 |

| SDCF271958-R25 | Yellow-Zinc Coated | 19 5/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 19 3/8 | 25 |

| SDCF272358 | Yellow-Zinc Coated | 23 5/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 23 3/8 | 100 |

| SDCF272358-R25 | Yellow-Zinc Coated | 23 5/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 23 3/8 | 25 |

| SDCF27400 | Yellow-Zinc Coated | 4 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 3 5/8 | 250 |

| SDCF27400-R30 | Yellow-Zinc Coated | 4 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 3 5/8 | 30 |

| SDCF27614 | Yellow-Zinc Coated | 6 1/4 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 6 | 250 |

| SDCF27614-R30 | Yellow-Zinc Coated | 6 1/4 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 6 | 30 |

| SDCF27778 | Yellow-Zinc Coated | 7 7/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 7 5/8 | 250 |

| SDCF27778-R30 | Yellow-Zinc Coated | 7 7/8 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 7 5/8 | 30 |

| SDCF27912 | Yellow-Zinc Coated | 9 1/2 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 9 1/8 | 250 |

| SDCF27912-R30 | Yellow-Zinc Coated | 9 1/2 | 0.725 | 0.290 | T50 6-Lobe | Flat Head with Nibs | 9 1/8 | 30 |

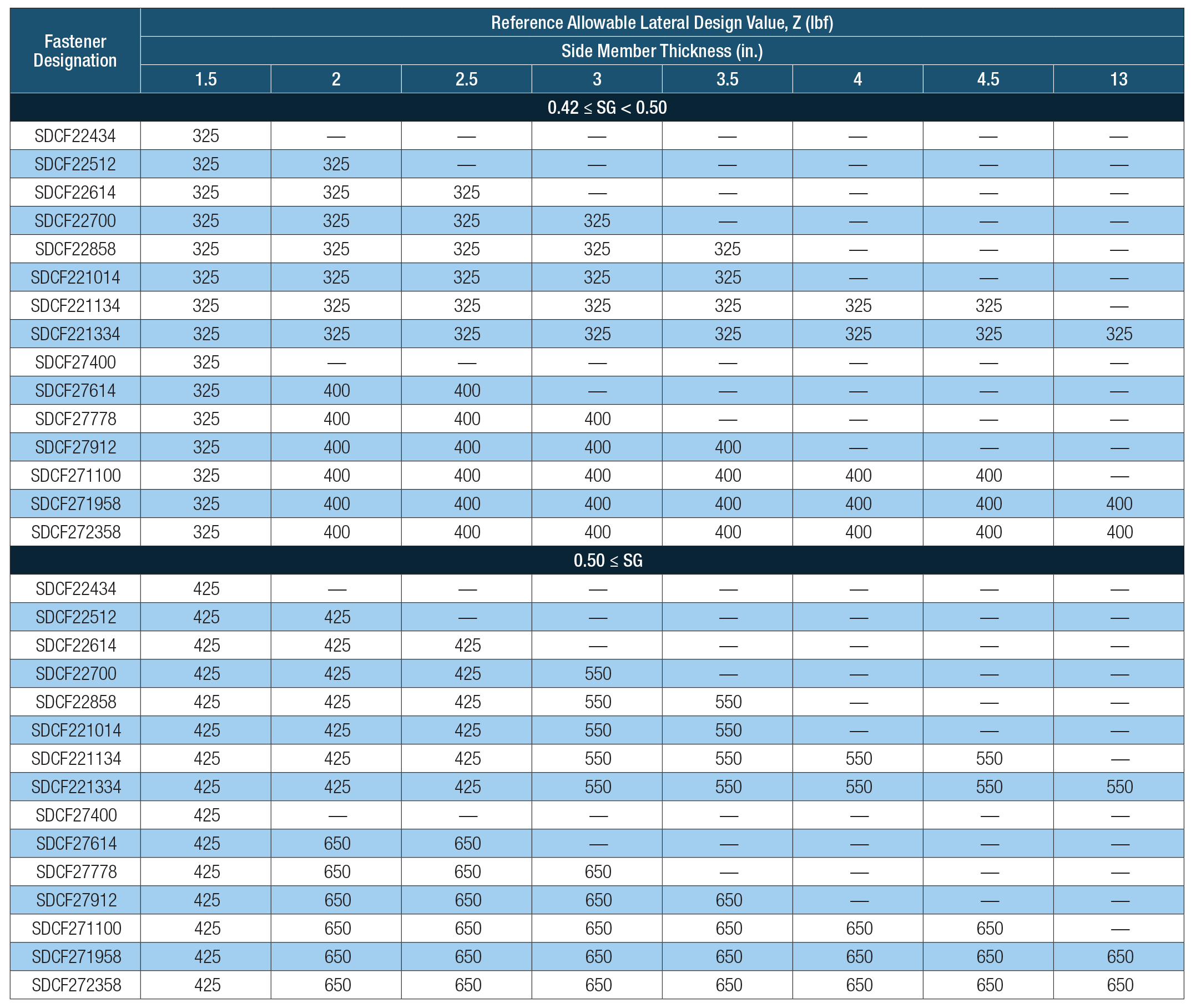

Load Tables

SDCF TIMBER-CF Screw — Allowable Lateral Design Values for Single Shear Wood-to-Wood Connections

- The main member and side members must be sawn lumber, glulam, or CLT with an assigned specific gravity (SG) as shown in the table above or an engineered wood product with a minimum grade of 1.3E and equivalent SG of at least 0.50.

- Tabulated reference allowable lateral design values (Z) must be multiplied by all applicable adjustment factors, including the load duration factor, CD, from the NDS as referenced in the IBC or IRC.

- Screws must be installed into the face or side grain of the wood main member with the screw axis at a 90-degree angle to the wood surface.

- Minimum fastener penetration must be equal to the screw length less the thickness of the wood side member.

- Tabulated reference lateral design values apply to combinations of parallel- and perpendicular-to-grain loading.

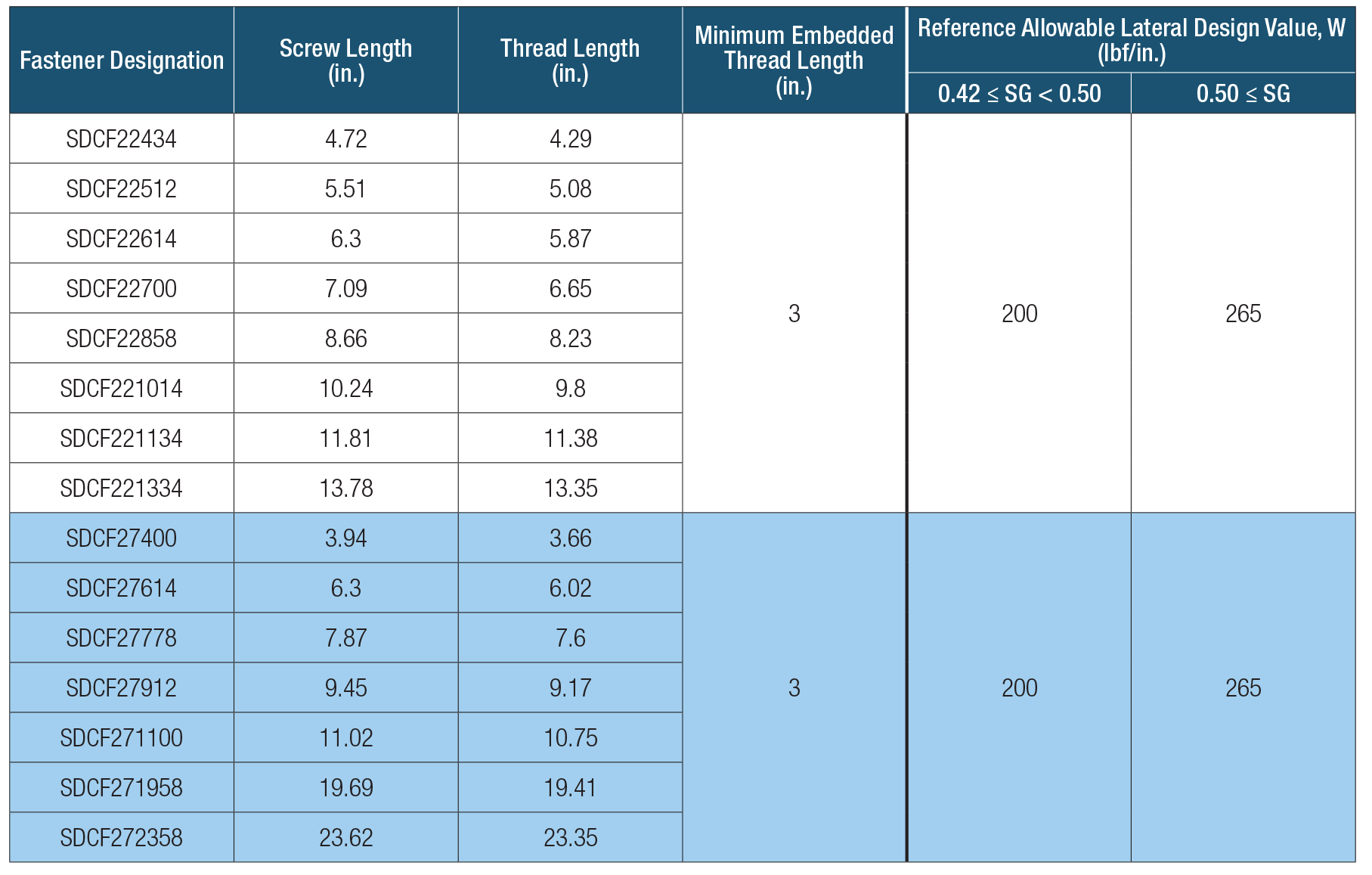

SDCF TIMBER-CF Screw — Allowable Withdrawal Design Values

- The tabulated reference allowable withdrawal design value, W, is in pounds per inch of the thread penetration into the side grain or face grain of the main member. Thread penetration is the portion of the threaded length held in the main member, including the screw point.

- The tabulated reference withdrawal design value, W, is given for a load duration of CD=1.0 and must be multiplied by all applicable adjustment factors from the NDS as referenced in the IBC or IRC.

- Wood main members must have an assigned specific gravity (SG) as indicated in the table above or for engineered wood products, a minimum grade of 1.3E and equivalent SG of 0.50.

- Reference allowable withdrawal values are for screws installed normal to the side grain of the wood members.

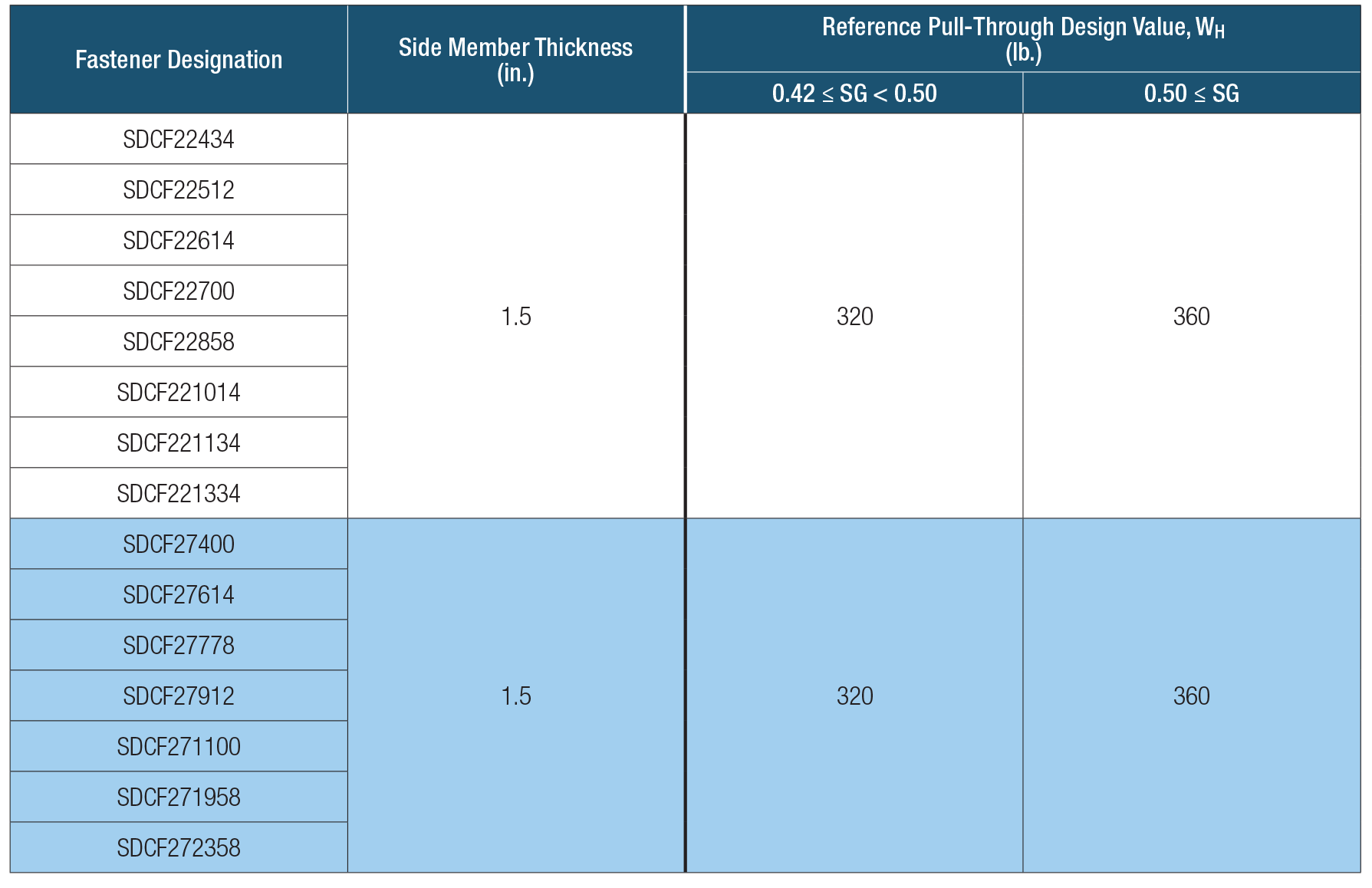

SDCF TIMBER-CF Screw — Allowable Head Pull-Through Design Values (WH)

- The side member must be solid-sawn lumber, glulam or CLT with an assigned specific gravity (SG) as indicated in the table above or for engineered wood products a minimum grade of 1.3E and equivalent SG of 0.50.

- Tabulated reference allowable pull-through design values (WH) must be multiplied by all applicable adjustment factors, including the load duration factor, CD, from the NDS as referenced in the IBC or IRC.

- Screws must be installed into the face or side grain of the wood side member with the screw axis at a 90° angle to the wood surface.

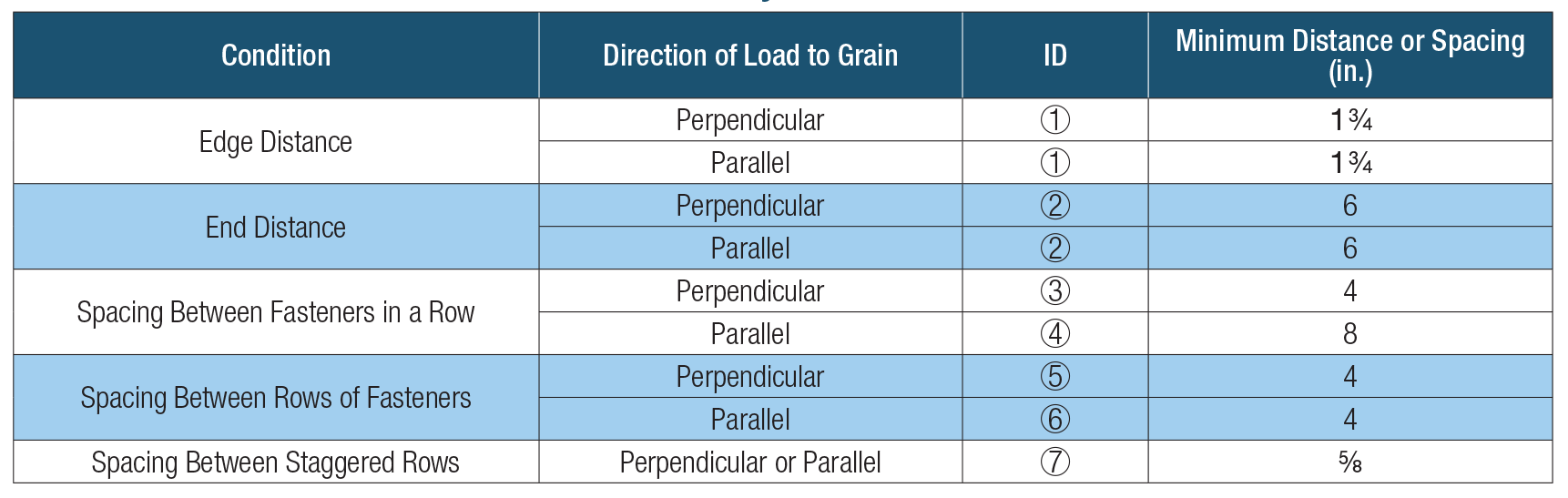

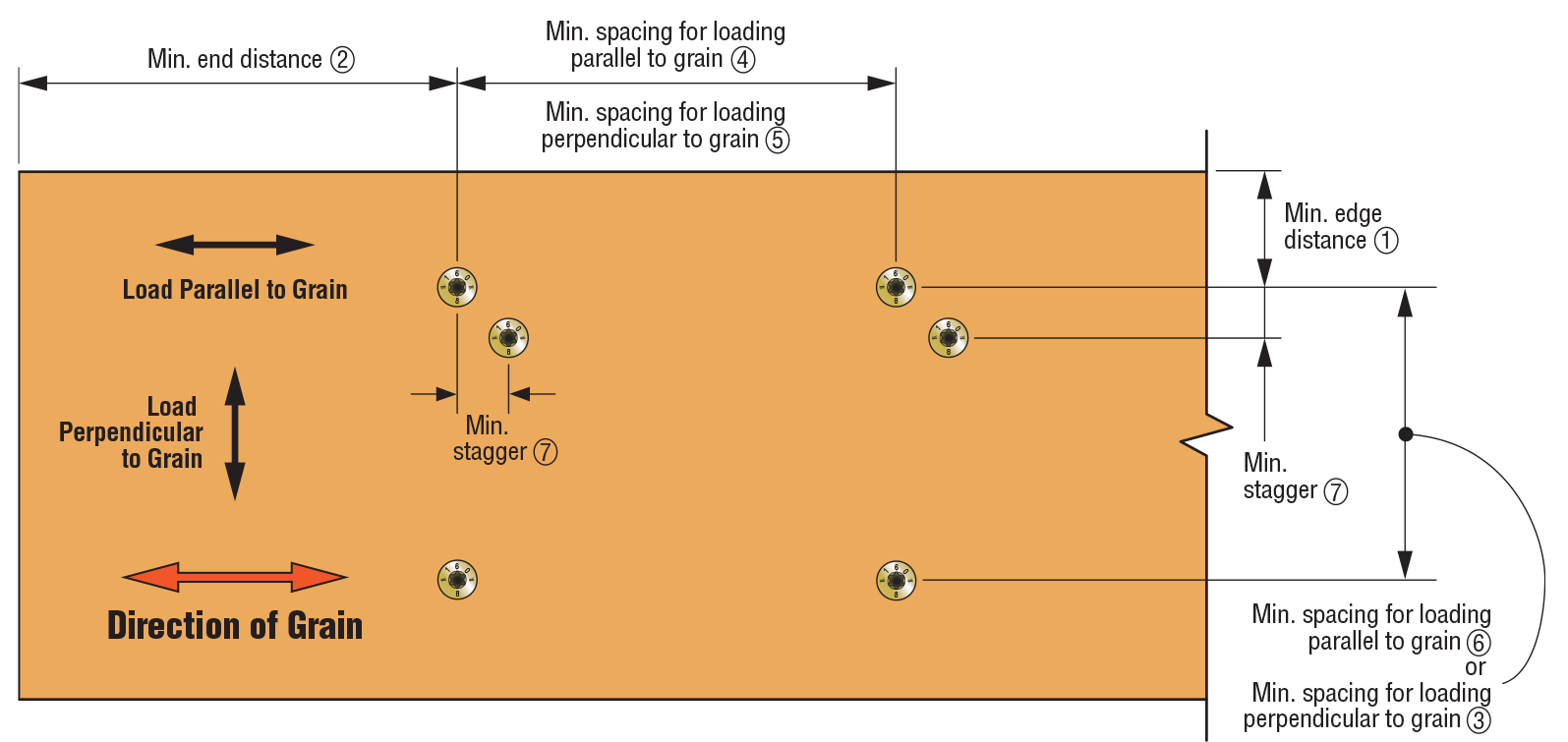

SDCF Screws Connection Geometry

- For SDCF22 screws subject to axial loading only, use the following minimum dimensions: end distance = 3 1/4", edge distance = 1 3/8", spacing parallel to grain = 2 1/4", spacing perpendicular to grain = 1 3/8".

- For SDCF27 screws subject to axial loading only, use the following minimum dimensions: end distance = 4", edge distance = 1 5/8", spacing parallel to grain = 2 7/8", spacing perpendicular to grain = 2".

SDCF Screw Spacing Requirements

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|