Strong-Drive® SDW™ EWP-PLY Screw

Fasteners for the Timber Drive™ System

This product's information may differ depending on the category of use. You are currently viewing details related to Fasteners for the Timber Drive™ System. You can also view product information related to the category: Strong-Drive® Interior Wood Screws

Product Details

The Strong-Drive SDW EWP-Ply screw is a high-strength structural wood screw specifically designed for fastening multi-ply members made up of engineered wood products. The SDW EWP-Ply installs easily with no predrilling and is available in optimized lengths for fastening 1 3/4" engineered lumber, such as structural composite lumber (SCL). The large, flush head eases the handling of assembled components and simplifies the installation of finishes or structural connectors. It is code listed in IAPMO UES ER-192 and meets 2018 and 2021 IRC® and IBC® code requirements for most common wood framing applications.

Key Features

- Large washer head with nibs provides maximum bearing area; stamped with the Simpson Strong-Tie “≠” sign and fastener length for easy identification after installation

- 6-lobe, T40 drive provides positive engagement that makes the screw easy to drive and improves bit life (replacement driver bit — BIT40T-134-R2)

- Low-profile head results in less interference after installation; makes stacking and sliding members easier and allows installation of hardware and finishes to be virtually flush

- Optimal screw lengths provide maximum penetration while preventing the point from protruding out the back of the member

- Specific thread lengths avoids jacking

- High shear values enable wide spacing, saving time and money

- Bold thread design provides superior holding power and cinches fastened members together for consistent installation

- SawTooth® point ensures fast starts, reduces installation torque and eliminates the need for predrilling in most applications

- Retail and mini-bulk packs include one 6-lobe, T40 driver bit; bulk packs include two driver bits

Applications

- Multi-ply wood members, engineered lumber products and solid sawn lumber

Patent Information

- US Patents 9,523,383; 11,181,138

Related Links

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), page 100

- Fastener Technical Data and Loads: C-F-2023TECHSUP, pages 125–130 and 133

Related Literature

Product Information Table

| Model No. | Coating/Material | Length (in.) | Head Diameter (in.) | Shank Diameter (in.) | Drive Type | Head Type | Thread Length (in.) | Point Type | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|---|

|

Footnotes

|

|||||||||

| SDW22338 | E-coat® Electrocoating | 3 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 900 |

| SDW22338MB | E-coat® Electrocoating | 3 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 250 |

| SDW22338-R50 | E-coat® Electrocoating | 3 3/8 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 50 |

| SDW22500 | E-coat® Electrocoating | 5 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 600 |

| SDW22500MB | E-coat® Electrocoating | 5 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 200 |

| SDW22500-R50 | E-coat® Electrocoating | 5 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 50 |

| SDW22634 | E-coat® Electrocoating | 6 3/4 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 500 |

| SDW22634MB | E-coat® Electrocoating | 6 3/4 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 200 |

| SDW22634-R50 | E-coat® Electrocoating | 6 3/4 | 0.760 | 0.220 | T40 6-Lobe | Low Profile Head | 1 1/2 | SawTooth® Point | 50 |

Product Information Table

| Model No. | Length (in.) | Drive Type | Head Type | Thread Length | Shank Diameter (in.) | Coating/Material | Packaging Quantity | UPC |

|---|---|---|---|---|---|---|---|---|

| SDW22338 | 3 3/8 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 900 | 707392147602 |

| SDW22338MB | 3 3/8 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 250 | 707392700708 |

| SDW22338-R50 | 3 3/8 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392769408 |

| SDW22500 | 5 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 600 | 707392268802 |

| SDW22500MB | 5 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392677109 |

| SDW22500-R50 | 5 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392367505 |

| SDW22634 | 6 3/4 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 500 | 707392855804 |

| SDW22634MB | 6 3/4 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 200 | 707392430209 |

| SDW22634-R50 | 6 3/4 | T-40 6-Lobe | Low Profile Head | 1 9/16 | 0.220 | E-Coat™ Electrocoating | 50 | 707392225300 |

Load Tables

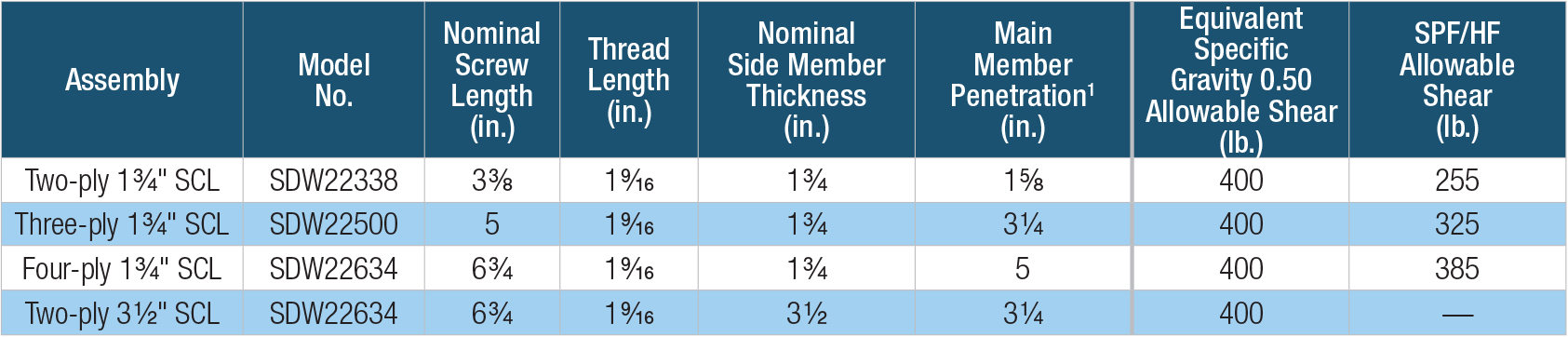

SDW EWP-PLY — Reference Allowable Shear Loads — LVL, PSL and LSL Loaded on Head Side

- For minimum penetration into main (outermost) member of 1 1/2", use 300 lb.

(Three-ply assembly shown — other configurations similar)

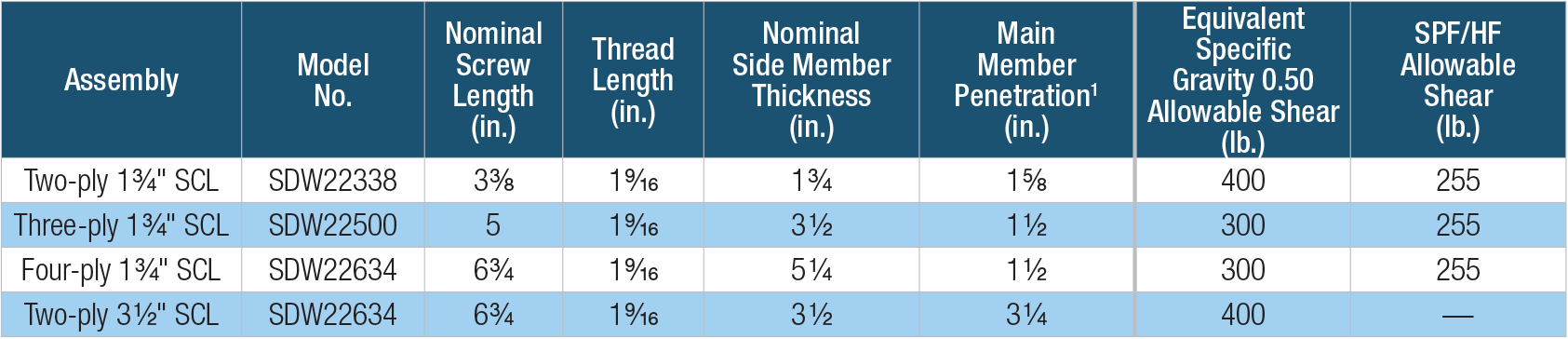

SDW EWP-PLY — Reference Allowable Shear Loads — LVL, PSL and LSL Loaded on Point Side

- For minimum penetration into main member of 1 1/2", use 300 lb.

(Three-ply assembly shown — other configurations similar)

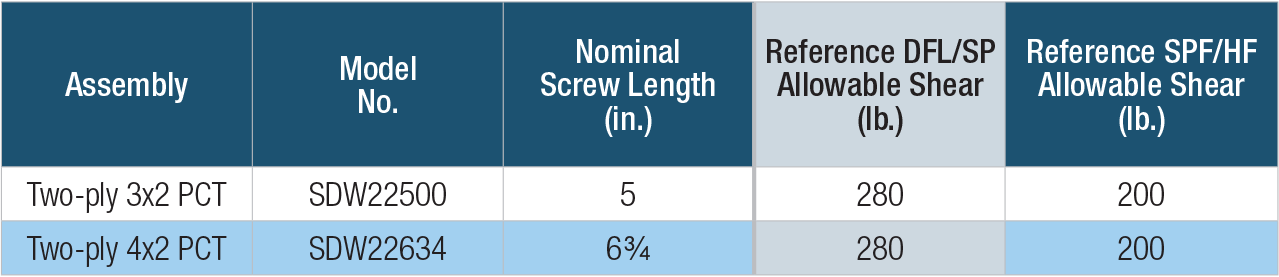

SDW EWP-PLY — Allowable Shear Loads — Two-Ply 3x2 / 4x2 Parallel-Chord Trusses Loaded on Either Side

- To transfer uniform or concentrated loads applied to simply supported spans on assembly top chord:

- Space screws as required to transfer half the load into the supporting truss.

- Minimum screw spacing shall be 4" o.c.

- To transfer concentrated loads applied to simply supported spans on an assembly top chord or vertical web:

- Concentrated loads must be applied at a panel point.

- Screws to be installed within 12" of the concentrated load on top-chord assembly.

- Gap between the trusses shall not exceed 1/8".

- Floor sheathing shall be screwed or nailed to each top-chord ply. (Fastener spacing per the applicable Code requirements, or 12" o.c.)

- SDW screws shall not be installed in areas where lumber wane exceeds 1/4".

- Hangers on skewed girders:

- Hanger loads not exceeding 34" o.c. on a skewed girder (resulting from uniformly spaced joists up to 24" o.c.) may be converted to a uniform load.

- For girders with hanger load spacing in excess of 34" o.c. the loads shall be considered as concentrated loads at the applicable locations.

- Other configurations acceptable when approved by Truss Designer.

(Two-ply 3x2 similar)

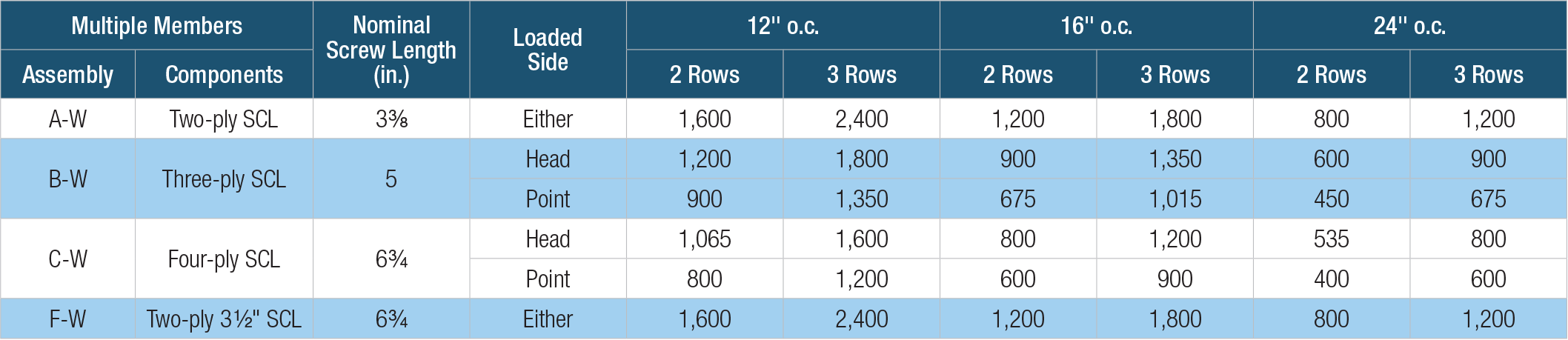

SDW EWP-PLY — Reference Allowable Uniform Load (plf) Applied to Either Outside Member — Side-Loaded Multi-Ply LVL, PSL, and LSL Assemblies

- Each ply is assumed to carry same proportion of load. Loads may be applied to the head side and point side concurrently provided neither published allowable load is exceeded. (Example: a three-ply assembly with a head side load of 1,300 plf and point side load of 1,000 plf may be fastened together with three rows of SDW at 16" o.c. between fasteners in a row.)

- When hangers are installed on point side, hanger face fasteners shall be a minimum of 3" long.

- Tables are based on main member penetration as noted in single-fastener load tables.

See additional Load Tables, Technical Data and Installation Instructions for the Strong-Drive® SDW EWP-Ply screw.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|