Yield-Link® Moment Connection (YLMC)

Product Details

At Simpson Strong-Tie, we've built a heritage of steel connection innovation. Through our tireless commitment to technological advancement, research and rigorous testing, our engineers have acquired an unparalleled body of expertise, with more patents and code-listed products than anyone else in the business. Our Yield-Link moment connection is precision-made to meet the tough demands and increased loads of structural steel construction. From building owners to engineers, to contractors and fabricators, the Yield-Link's state-of-the-art design saves everyone time and money — while providing a connection that keeps structural steel buildings strong and safe.

Key Features

- Saves time and costs on fabrication and erection

- Requires no onsite welding of moment connection, reducing welding inspection costs

- Replaceable Yield-Links allow for less costly repairs and shorter recovery times

- Accepted into AISC 358-16 and code listed in ICC-ES ESR-2802

- Can be integrated into your design software and can be designed without beam bracing

- Reduces difficult coordination between welders and inspectors

- No delays for field welding and welding inspection of the moment connection

- Small restricted zone for easier MEP coordination

- All shop welds are fillet welds, providing a simple fabrication process

Patent Information

- US Patents 11,072,938; 10,669,718

Related Links

Related Literature

Product Information Table

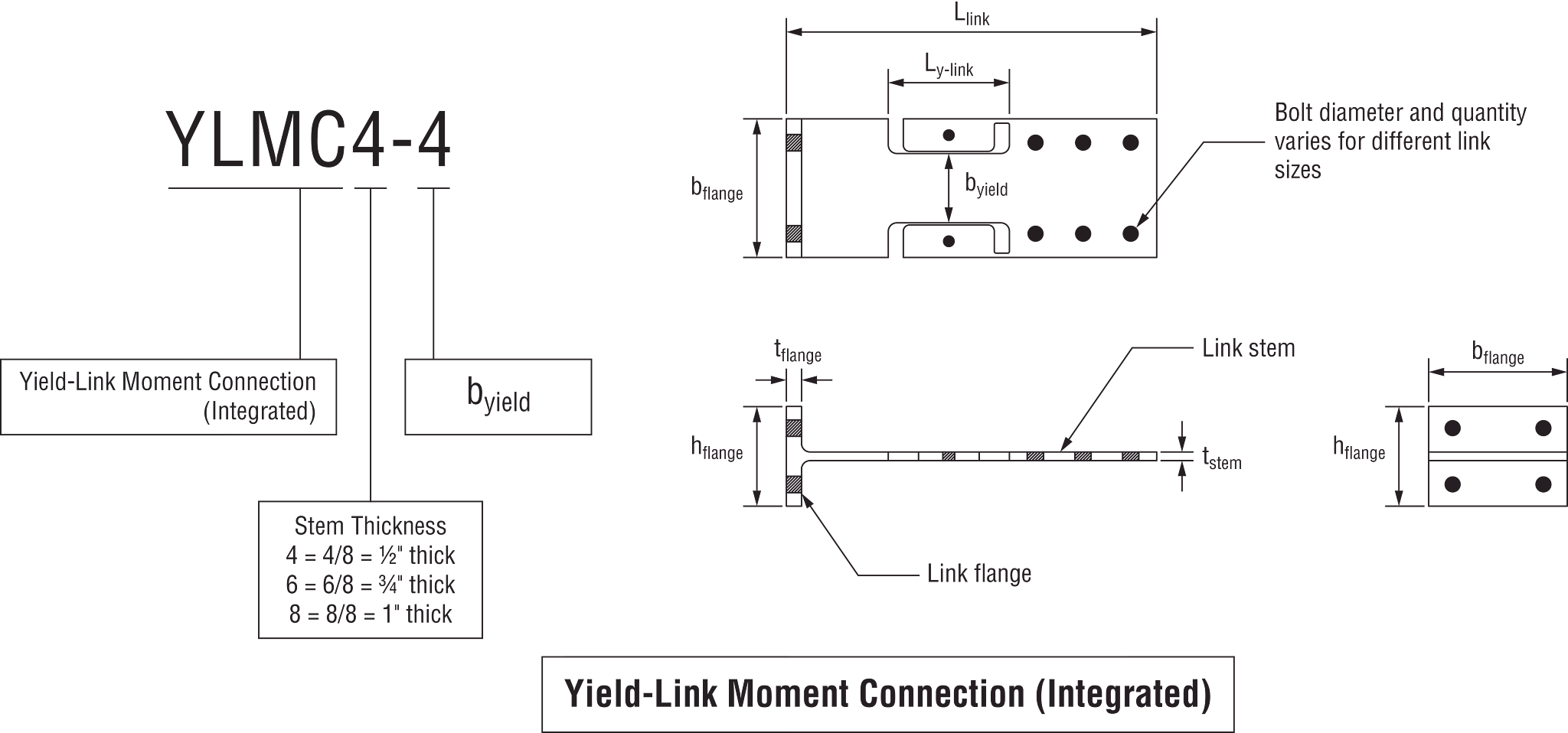

The YLMC SKUs have spacers that have been integrated into the Yield-Link structural fuses.

| Geometry | |||

|---|---|---|---|

| Yield-Link Series | tstem (in.) |

tflange (in.) |

hflange (in.) |

| YLMC4 | 1/2 | 7/8 | 5 3/4 |

| YLMC4-x-10 | 13/16 | ||

| YLMC6 & YLMC6-x-13 | 3/4 | 1 1/4 | 9 1/4 |

| YLMC8 & YLMC8-x-15 | 1 | 1 13/16 | 10 3/4 |

| Yield-Link® SKU | Geometry | Design Information | Bolts Information, Quantity and Dia. | Included Kit Component | ||||||||||||||||||||||||||||||||||||

| Lyield (in.) |

Llink (in.) |

bflange (in.) |

Py_link (kips) |

Keff (kip/in.) |

Beam Depth | Link Flange (in.) | Link Stem (in.) | BRP (in.) |

BRP ID | |||||||||||||||||||||||||||||||

| Min. | Max. | |||||||||||||||||||||||||||||||||||||||

| YLMC4-2 | 7 | 18 5/8 | 6 1/4 | 50.00 | 2970 | W12 | W18 | (4) 7/8 | (4) 7/8 | (2) 5/8 | BRP4C | |||||||||||||||||||||||||||||

| YLMC4-2.5 | 62.50 | 3468 | ||||||||||||||||||||||||||||||||||||||

| YLMC4-3 | 6 1/2 | 75.00 | 3960 | |||||||||||||||||||||||||||||||||||||

| YLMC4-2.25 | 7 | 56.25 | 3337 | BRP4A | ||||||||||||||||||||||||||||||||||||

| YLMC4-2.875 | 71.88 | 3953 | ||||||||||||||||||||||||||||||||||||||

| YLMC4-3.375 | 21 3/8 | 7 | 84.38 | 4138 | 6 7/8 | |||||||||||||||||||||||||||||||||||

| YLMC4-3.5 | 8 | 87.50 | 4460 | BRP4B | ||||||||||||||||||||||||||||||||||||

| YLMC4-4 | 100.00 | 4831 | ||||||||||||||||||||||||||||||||||||||

| YLMC4-2.25-10 | 10 | 21 9/16 | 7 | 56.25 | 2554 | W16 | W27 | (4) 7/8 | (4) 7/8 | (4) 5/8 | BRP4A-10 | |||||||||||||||||||||||||||||

| YLMC4-2.875-10 | 71.88 | 3077 | ||||||||||||||||||||||||||||||||||||||

| YLMC4-3.375-10 | 24 5/16 | 7 | 84.38 | 3262 | 6 7/8 | |||||||||||||||||||||||||||||||||||

| YLMC4-3.5-10 | 8 | 87.50 | 3529 | BRP4B-10 | ||||||||||||||||||||||||||||||||||||

| YLMC4-4-10 | 100.00 | 3865 | ||||||||||||||||||||||||||||||||||||||

| YLMC6-2.5 | 10 | 27 1/2 | 6 1/2 | 93.75 | 3426 | W16 | W27 | (4) 7/8 | (6) 7/8 | (4) 3/4 | BRP6D | |||||||||||||||||||||||||||||

| YLMC6-3 | 8 | 112.50 | 4149 | (4) 1 | (6) 1 | BRP6A | ||||||||||||||||||||||||||||||||||

| YLMC6-3.5 | 131.25 | 4564 | ||||||||||||||||||||||||||||||||||||||

| YLMC6-4 | 150.00 | 4933 | (4) 1 1/4 | |||||||||||||||||||||||||||||||||||||

| YLMC6-4.5 | 10 | 168.75 | 5801 | (6) 1 1/4 | BRP6B | |||||||||||||||||||||||||||||||||||

| YLMC6-5 | 187.50 | 6167 | ||||||||||||||||||||||||||||||||||||||

| YLMC6-5.5 | 12 | 206.25 | 7037 | BRP6C | ||||||||||||||||||||||||||||||||||||

| YLMC6-6 | 225.00 | 7400 | (4) 1 3/8 | |||||||||||||||||||||||||||||||||||||

| YLMC6-3-13 | 13 | 30 1/2 | 8 | 112.50 | 3484 | W24 | W36 | (4) 1 | (6) 1 | (4) 3/4 | BRP6A-13 | |||||||||||||||||||||||||||||

| YLMC6-3.5-13 | 131.25 | 3868 | ||||||||||||||||||||||||||||||||||||||

| YLMC6-4-13 | 150.00 | 4216 | (4) 1 1/14 | |||||||||||||||||||||||||||||||||||||

| YLMC6-4.5-13 | 10 | 168.75 | 4925 | (6) 1 1/14 | BRP6B-13 | |||||||||||||||||||||||||||||||||||

| YLMC6-5-13 | 187.50 | 5270 | ||||||||||||||||||||||||||||||||||||||

| YLMC6-5.5-13 | 12 | 206.25 | 5981 | BRP6C-13 | ||||||||||||||||||||||||||||||||||||

| YLMC6-6-13 | 225 | 6324 | (4) 1 3/8 | |||||||||||||||||||||||||||||||||||||

| YLMC8-4 | 13 | 31 1/6 | 9 | 200.00 | 6034 | W24 | W36 | (4) 1 3/8 | (6) 1 1/4 | 4 3/4 | BRP8A | |||||||||||||||||||||||||||||

| YLMC8-4.5 | 225.00 | 6524 | (4) 1 3/8 | |||||||||||||||||||||||||||||||||||||

| YLMC8-5 | 34 7/16 | 12 | 250.00 | 7698 | (8) 1 1/4 | BRP8B | ||||||||||||||||||||||||||||||||||

| YLMC8-5.5 | 275.00 | 8213 | (4) 1 1/2 | |||||||||||||||||||||||||||||||||||||

| YLMC8-6 | 300.00 | 8698 | ||||||||||||||||||||||||||||||||||||||

| YLMC8-4-15 | 15 | 33 1/16 | 9 | 200.00 | 5465 | W24 | W36 | (4) 1 1/4 | (6) 1 1/4 | (6) 3/4 | BRP8A-15 | |||||||||||||||||||||||||||||

| YLMC8-4.5-15 | 225.00 | 5931 | (4) 1 3/8 | |||||||||||||||||||||||||||||||||||||

| YLMC8-5-15 | 36 7/16 | 12 | 250.00 | 6959 | (8) 1 1/4 | BRP8B-15 | ||||||||||||||||||||||||||||||||||

| YLMC8-5.5-15 | 275.00 | 7446 | (4) 1 1/2 | |||||||||||||||||||||||||||||||||||||

| YLMC8-6-15 | 300.00 | 7908 | ||||||||||||||||||||||||||||||||||||||

- The YLMC configurations are equivalent to the former YL configurations. However, YL configurations are required for OSHPD/HCAI and DSA projects. Please see the YL product information page for more information.

- Link Stem-to-beam flange bolts shall be ASTM F3125 Grade A490 or F2280 (X or N) (Pretensioned)

- Link Flange-to-column flange bolts shall be ASTM F3125 Grade A325-N (Snug-tight) or F1852-N (Pretensioned)

- Shear Plate-to-beam web bolts shall be ASTM F3125 Grade A325, A490, F1852 or F2280 (X or N type per design)

- BRP-to-beam flange bolts shall be ASYTM F3125 Grade A325-N (A3250X for YLMC8-6 & YLMC8-6-15)

- A Simpson Strong-Tie patent label, provided by Simpson Strong-Tie Company Inc., must be applied adjacent to each moment connection. Simpson Strong-tie Strong Frame® and the Yield-link Moment Connection Structural fuse are protected under one or more of the following U.S. patents and applications: U.S. Patent No. 8,001,734 B2, U.S. Patent No. 8,375,652 B2, U.S. Patent Publication No. 2015/0159362, And U.S. Patent Publication No. 15/935,412 and must be supplied or licensed through Simpson Strong-tie. Yield-link Moment Connection is manufactured and protected under U.S. Patent No. 10,669,718 B2 and cannot be duplicated or fabricated without expressed, written permission from Simpson Strong-tie Co., Inc.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|