Strong-Drive® SDWH™ TIMBER-HEX SS Screw

Strong-Drive® Exterior Wood Screws

This product's information may differ depending on the category of use. You are currently viewing details related to Strong-Drive® Exterior Wood Screws. You can also view product information related to the category: Fasteners for the Timber Drive™ System

Product Details

The Strong-Drive® SDWH TIMBER-HEX SS screw is a stainless-steel structural fasteners designed for lag-screw replacement. These 0.185" and 0.275" diameter hex-head fasteners require no predrilling, making them easier and faster to install than typical lag screws. It meets 2018 and 2021 IRC® and IBC® code requirements for most common wood framing applications.

Key Features

- Type 316 stainless steel for maximum corrosion protection

- No predrilling necessary in most applications

- Driver bit included (replacement driver bit — BITHEXR516-R1 or BITHEXR12-R1)

- Can be used in ledger applications

- Unique “box” thread design with raised-ridge technology significantly reduces driving torque

- Hex-washer head provides large bearing area

Applications

- Structural wood-to-wood and engineered-wood connections, including ledger

Product Includes

- Retail clamshells, cartons and buckets include hex driver bit

Related Links

Catalog Pages

- Fastener Product Information: C-F-2023 (Fastening Systems), page 62

- Fastener Technical Data and Loads: C-F-2023TECHSUP, pages 64–65 and pages 164–165 and 167-169

Related Literature

Product Information Table

| Model No. | Coating/Material | Length (in.) | Head Diameter (in.) | Shank Diameter (in.) | Drive Type | Head Type | Thread Type | Thread Length (in.) | Point Type | Packaging Qty. |

|---|---|---|---|---|---|---|---|---|---|---|

|

Footnotes

|

||||||||||

| SDWH19400SS-R100 | Type 316 Stainless Steel | 4 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 100 |

| SDWH19400SS-R20 | Type 316 Stainless Steel | 4 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 20 |

| SDWH19450SS-R10 | Type 316 Stainless Steel | 4 1/2 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/4 | Sharp Point | 10 |

| SDWH19450SS-R100 | Type 316 Stainless Steel | 4 1/2 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/4 | Sharp Point | 100 |

| SDWH19500SS-R10 | Type 316 Stainless Steel | 5 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 10 |

| SDWH19500SS-R100 | Type 316 Stainless Steel | 5 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 100 |

| SDWH19600SS-R10 | Type 316 Stainless Steel | 6 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 10 |

| SDWH19600SS-R100 | Type 316 Stainless Steel | 6 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 100 |

| SDWH19800SS-R10 | Type 316 Stainless Steel | 8 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 10 |

| SDWH19800SS-R50 | Type 316 Stainless Steel | 8 | 0.455 | 0.185 | 5/16 in. Hex | Hex Washer Head | Box Threads | 2 3/8 | Sharp Point | 50 |

| SDWH271000SS-R25 | Type 316 Stainless Steel | 10 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 25 |

| SDWH271000SS-R5 | Type 316 Stainless Steel | 10 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 5 |

| SDWH271000SS-RP1 | Type 316 Stainless Steel | 10 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

| SDWH271200SS-R25 | Type 316 Stainless Steel | 12 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 25 |

| SDWH271200SS-R5 | Type 316 Stainless Steel | 12 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 5 |

| SDWH27300SS-R10 | Type 316 Stainless Steel | 3 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 10 |

| SDWH27300SS-R100 | Type 316 Stainless Steel | 3 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 100 |

| SDWH27300SS-RP1 | Type 316 Stainless Steel | 3 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

| SDWH27400SS-R10 | Type 316 Stainless Steel | 4 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 10 |

| SDWH27400SS-R100 | Type 316 Stainless Steel | 4 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 100 |

| SDWH27400SS-RP1 | Type 316 Stainless Steel | 4 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

| SDWH27500SS-R10 | Type 316 Stainless Steel | 5 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 10 |

| SDWH27500SS-R50 | Type 316 Stainless Steel | 5 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 50 |

| SDWH27500SS-RP1 | Type 316 Stainless Steel | 5 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

| SDWH27600SS-R10 | Type 316 Stainless Steel | 6 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 10 |

| SDWH27600SS-R50 | Type 316 Stainless Steel | 6 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 50 |

| SDWH27600SS-RP1 | Type 316 Stainless Steel | 6 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

| SDWH27800SS-R10 | Type 316 Stainless Steel | 8 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 10 |

| SDWH27800SS-R25 | Type 316 Stainless Steel | 8 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 25 |

| SDWH27800SS-RP1 | Type 316 Stainless Steel | 8 | 0.655 | 0.275 | 1/2 in. Hex | Hex Washer Head | Box Threads | 3 | Sharp Point | 1 |

Product Information Table

| Model No. | Length (in.) | Drive Type | Head Diameter (in.) | Head Type | Thread Length | Thread Type | Shank Diameter (in.) | Point Type | Coating/Material | Packaging Quantity | UPC |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SDWH19400SS-R100 | 4 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 100 | 707392305941 |

| SDWH19400SS-R20 | 4 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 20 | 707392270690 |

| SDWH19450SS-R10 | 4 1/2 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.75 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 10 | 707392167334 |

| SDWH19450SS-R100 | 4 1/2 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.75 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 100 | 707392186922 |

| SDWH19500SS-R10 | 5 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 10 | 707392573319 |

| SDWH19500SS-R100 | 5 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 100 | 707392202974 |

| SDWH19600SS-R10 | 6 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 10 | 707392271154 |

| SDWH19600SS-R100 | 6 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 100 | 707392783794 |

| SDWH19800SS-R10 | 8 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 10 | 707392257875 |

| SDWH19800SS-R50 | 8 | 5/16 in. Hex | 0.455 | Hex Washer Head | 2.40 | Box Threads | 0.188 | Sharp Point | Type 316 Stainless Steel | 50 | 707392160434 |

| SDWH271000SS-R25 | 10 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 25 | 707392585336 |

| SDWH271000SS-R5 | 10 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 5 | 707392472360 |

| SDWH271200SS-R25 | 12 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 25 | 707392107453 |

| SDWH271200SS-R5 | 12 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 5 | 707392791454 |

| SDWH27300SS-R10 | 3 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 10 | 707392915829 |

| SDWH27300SS-R100 | 3 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 100 | 707392561712 |

| SDWH27400SS-R10 | 4 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 10 | 707392832935 |

| SDWH27400SS-R100 | 4 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 100 | 707392211648 |

| SDWH27500SS-R10 | 5 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 10 | 707392475934 |

| SDWH27500SS-R50 | 5 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 50 | 707392113461 |

| SDWH27600SS-R10 | 6 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 10 | 707392216032 |

| SDWH27600SS-R50 | 6 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 50 | 707392753735 |

| SDWH27800SS-R10 | 8 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 10 | 707392557623 |

| SDWH27800SS-R25 | 8 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 25 | 707392650379 |

| SDWH271000SS-RP1 | 10 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392194767 |

| SDWH27300SS-RP1 | 3 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392556282 |

| SDWH27400SS-RP1 | 4 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392589792 |

| SDWH27500SS-RP1 | 5 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392539070 |

| SDWH27600SS-RP1 | 6 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392149538 |

| SDWH27800SS-RP1 | 8 | 1/2 in. Hex | 0.655 | Hex Washer Head | 2.95 | Box Threads | 0.276 | Sharp Point | Type 316 Stainless Steel | 1 | 707392277743 |

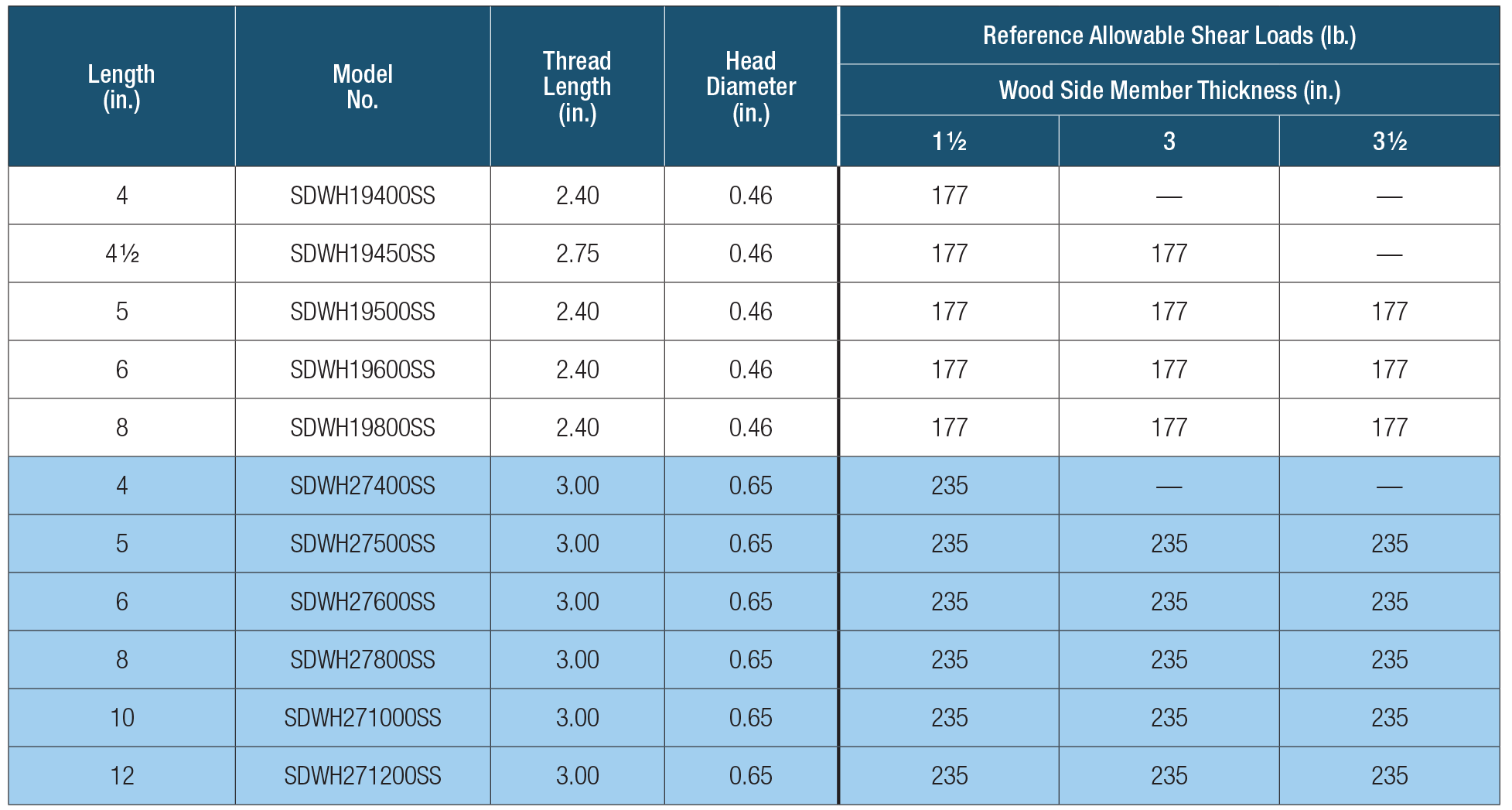

Load Tables

SDWH SS — Allowable Shear Loads-Douglas Fir–Larch, Southern Pine, Spruce-Pine-Fir, Hem-Fir

Note: See table below for spacing requirements.

- All applications are based on full penetration into the main member. Full penetration is the screw length minus the side member thickness.

- Allowable loads are shown at the load duration factor of CD = 1.0. Loads may be increased for load duration per the building code up to a CD = 1.6. Tabulated values must be multiplied by all applicable adjustment factors per the NDS.

- Table values based on testing in SPF lumber.

- Design values include NDS wet service factor; no adjustment required for in-service moisture content greater than 19%.

- Allowable loads are perpendicular or parallel to grain.

- Installs best with 18v high-torque cordless or 1/2" low speed drill. If splitting occurs predrill with 5/32" drill bit for SDWH19 screws and 7/32" drill bit for 0.276" screws.

- Allowable withdrawal load for the SDWH19 screw for DFL/SP is 155 lb./in. and for SPF/HF is 108 lb./in. Allowable load is based on inches of thread penetration into the main member.

- Allowable withdrawal load for the SDWH27 screw for DFL/SP is 260 lb./in. and for SPF/HF is 160 lb./in. Allowable load is based on inches of thread penetration into the main member.

- For LRFD values, the reference connection design values shall be adjusted in accordance with NDS-18, section 11.3.

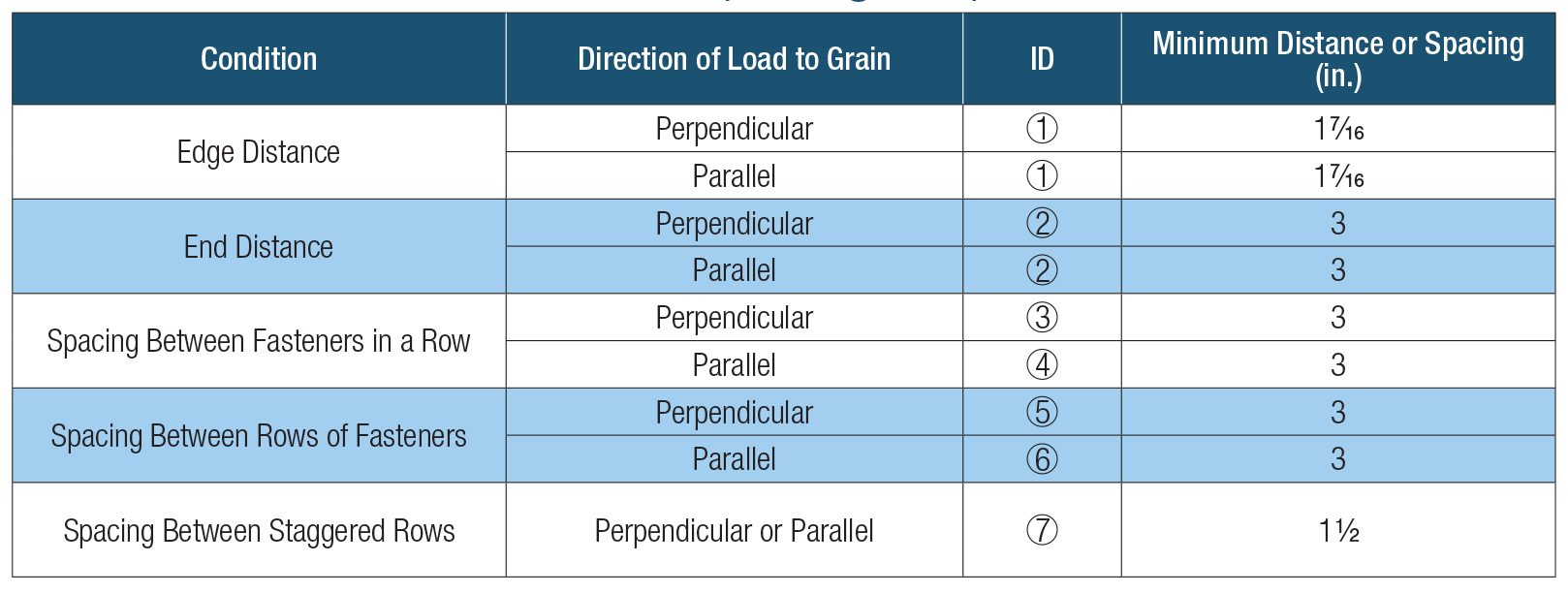

SDWH Timber-Hex SS Screw Spacing Requirements

- For SDWH19 screws subject to axial loading only, use the following minimum dimensions: end distance: = 2 3/8", edge distance = 1", spacing parallel to grain = 1 5/8", spacing perpendicular to grain = 1".

- For SDWH27 screws subject to axial loading only, use the following minimum dimensions: end distance = 3 1/4", edge distance = 1 3/8", spacing parallel to grain = 2 3/8", spacing perpendicular to grain = 1 5/8".

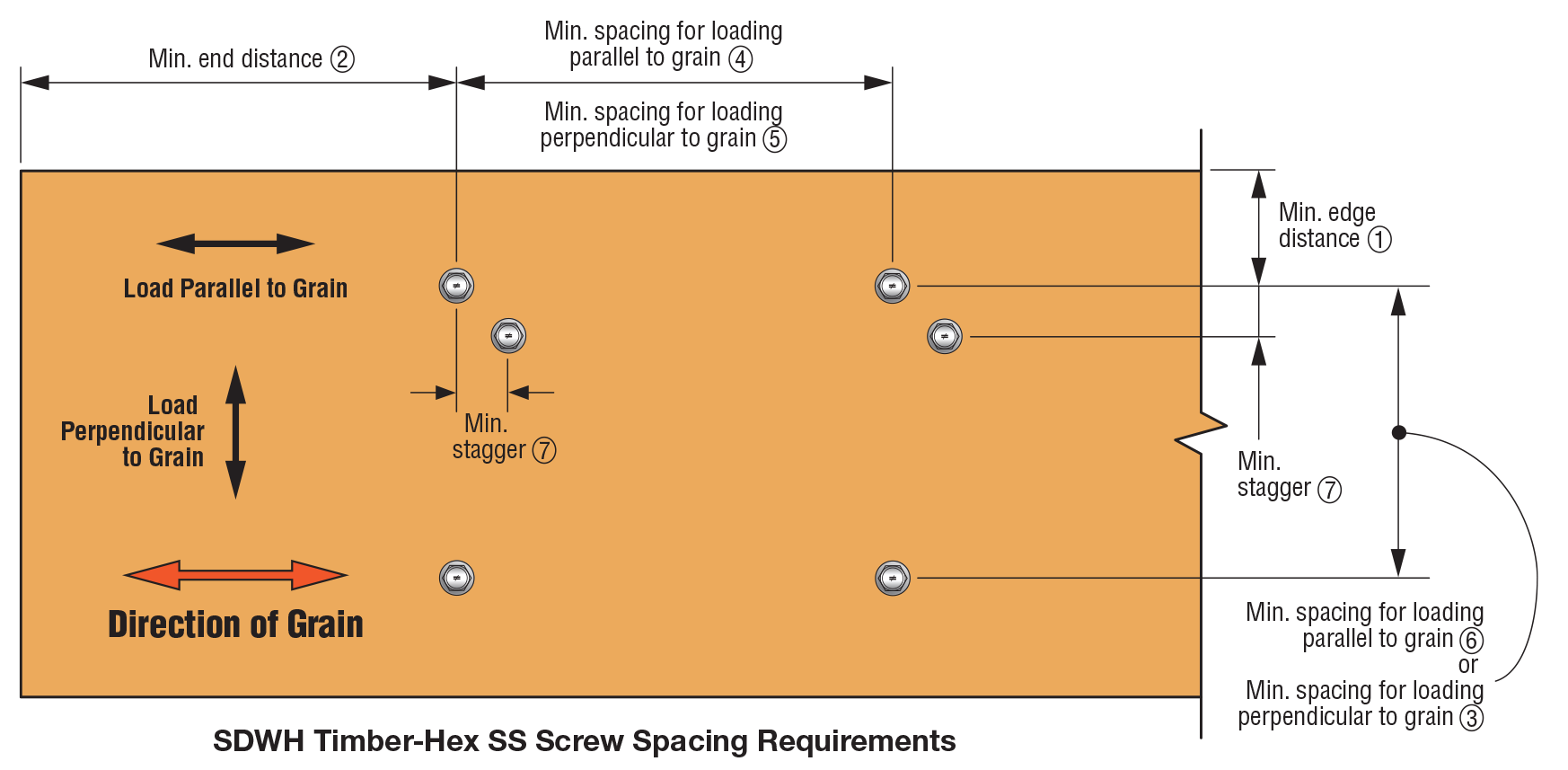

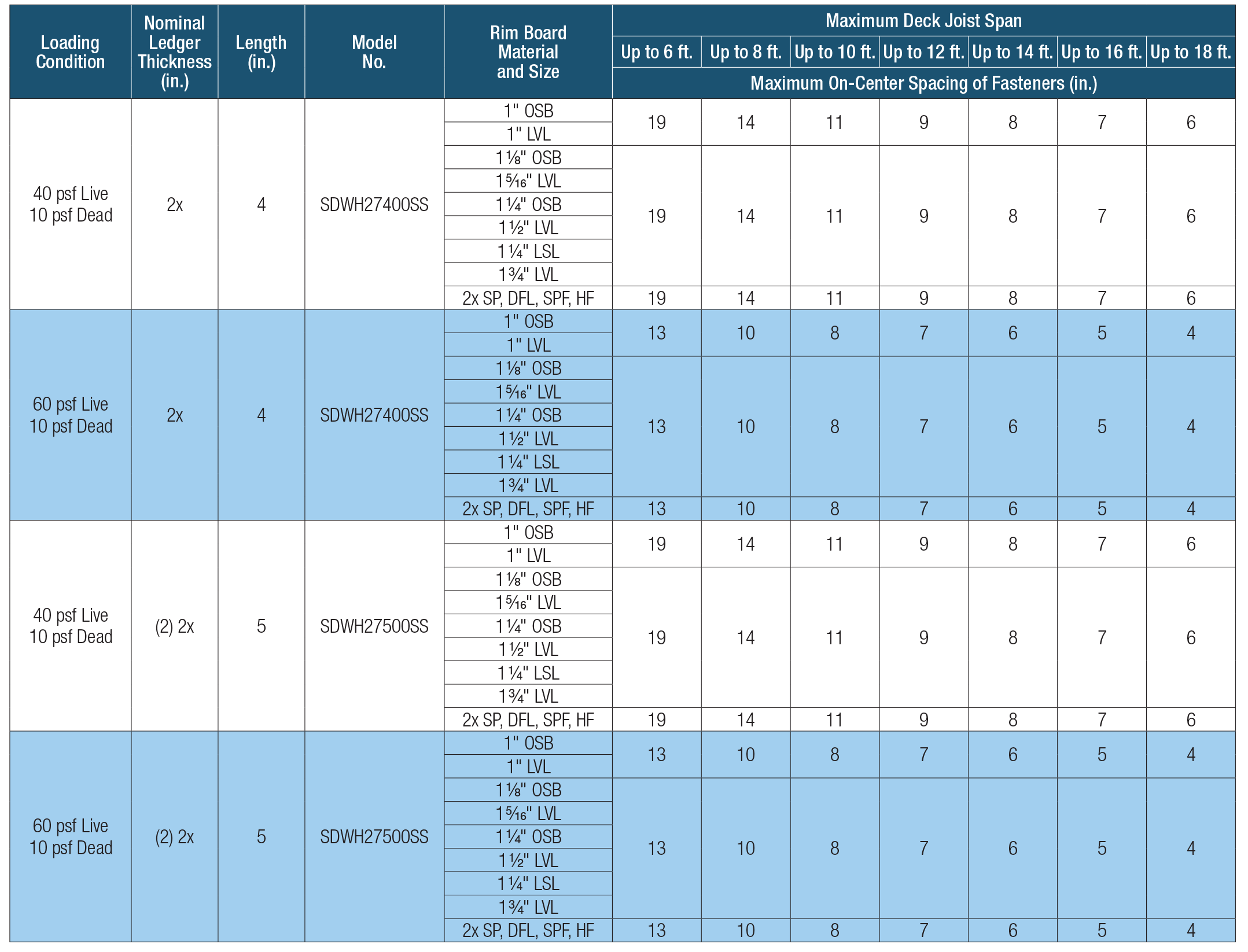

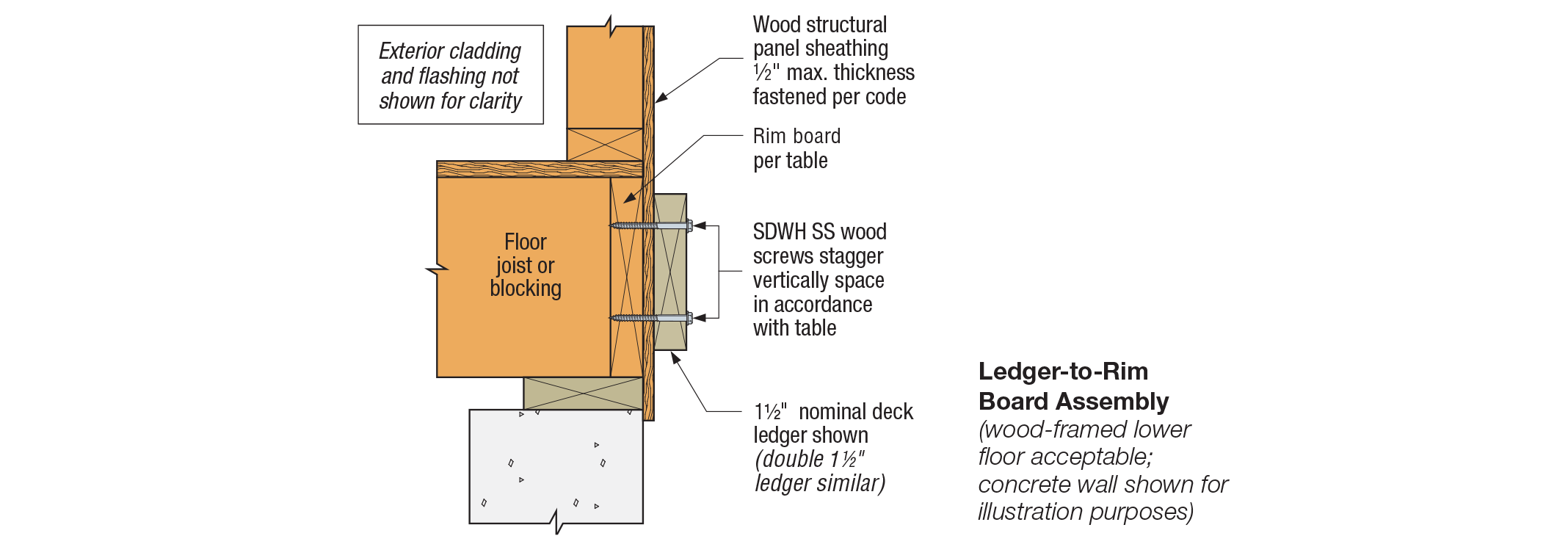

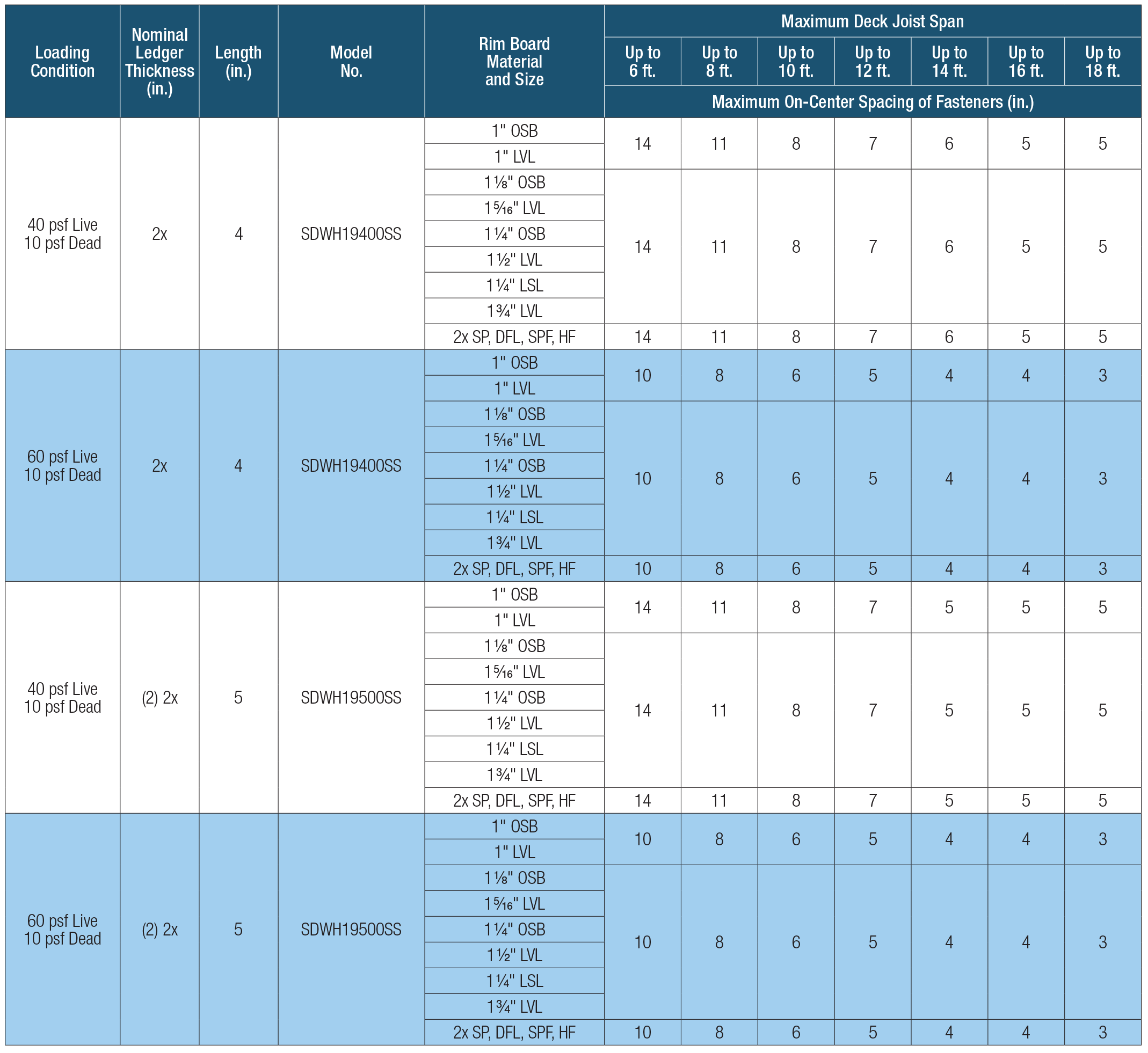

SDWH Timber-Hex SS Screw — 2021 and 2018 IRC Compliant Spacing for a Sawn Lumber Deck Ledger-to-Rim Board — SDWH27 Screws

- See footnotes below.

SDWH Timber-Hex SS Screw — 2021 and 2018 IRC Compliant Spacing for a Sawn Lumber Deck Ledger-to-Rim Board — SDWH19 Screws

- Screw spacing values are equivalent to 2021/2018 IRC Table R507.9.1.3(1) and 2015 IRC Table R507.2. The table above also provides screw spacing for a wider range of materials commonly used for band joists, and an alternate loading condition as required by some jurisdictions.

- Sawn rim board shall be spruce-pine-fir, hem-fir, Douglas fir–larch, or southern pine species. Ledger shall be hem-fir, Douglas fir–larch, or southern pine species.

- Fastener spacings are based on the lesser of single fastener ICC-ES AC233 testing with a safety factor of 5.0 or ledger assembly testing with a factor of safety of 5.0. Spacing includes NDS wet service factor adjustment.

- Multiple ledger plies shall be fastened together per code independent of the screws.

- Screws shall be placed 1.5" to 2" from the top and bottom of the ledger or rim board with 3" minimum and 6" maximum vertical distance between fasteners with horizontal on-center spacing per the table. End screws shall be located 6" from the end and at 1.5" to 2" from the bottom of the ledger. For screws located at least 2" but less than 6" from the end, use 50% of the load per screw and 50% of the table spacing between the end screw and the adjacent screw, and for screws located between 2" and 4" from the end, predrill using a 5/32" drill bit for SDWH19SS and 7/32" drill bit for SDWH27SS.

- Structural sheathing between the ledger and band shall be a maximum of 1/2" thick and fastened per code.

- See Ledger-to-Rim Board Assembly image above.

- Visit the Drawing Finder for additional ledger fastening detail sheets and load tables in DWG, PDF or DXF format.

Note: See the Fastening Systems Technical Guide and refer to the Alphabetical Index for additional load tables, technical data and installation instructions for the Strong-Drive® SDWH Timber-Hex SS screw.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|