S/LTT Light Tension Tie

Product Details

The S/LTT tension tie is designed for lighter-duty hold-down (holdown) or tension tie applications. The light tension tie provides post-pour, concrete-to-steel connections. They easily install with #10 self-drilling screws into the stud.

Key Features

- Ideal for retrofit or new construction projects

- Can be installed with cast-in-place or post-installed anchor bolts

- Load-transfer plate resists the deflection around the anchor bolt

Material

- 97 mil (12 ga.)

Finish

- Galvanized (G90)

Installation

- Use all specified fasteners.

- Use the specified number of type of screws to attach the strap portion to the steel stud. Bolt the base to the wall or foundation with a suitable anchor; see table for the required bolt diameter.

- Do not install S/LTT20 raised off of the bottom track.

Options

- Special sizes can be made to order; contact Simpson Strong-Tie

Related Literature

Product Information Table

| Model No. | Thickness (mil) | Ga. | W (in.) | H (in.) | Coating/Material | Packaging Qty. |

|---|---|---|---|---|---|---|

| S/LTT20 | 97 strap, 229 plate | 12 strap, 3 plate | 2 | 20 | Zinc Galvanized, G90 | 1 |

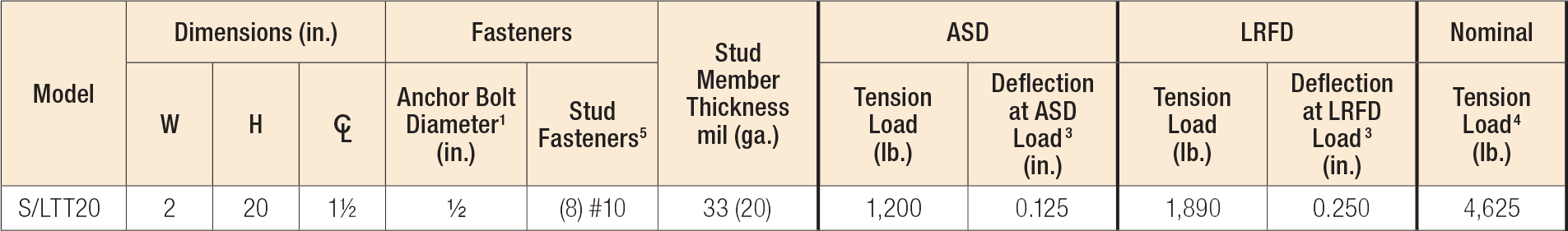

Load Tables

- The designer shall specify the foundation anchor material type, embedment and configuration.

- Stud design by specifier. Tabulated loads are based on a minimum stud thickness for fastener connection.

- Deflection at ASD or LRFD includes fastener slip, holdown deformation and anchor rod elongation for holdowns installed up to 4" above top of concrete. Holdowns may be installed raised, up to 18" above top of concrete, with no load reduction provided that additional elongation of the anchor rod is accounted for. See S/HDU holdown for installation detail.

- The Nominal Tension Load is based on the tested average ultimate (peak) load and is provided for design in accordance with section C5 of AISI S213 that requires a tension tie to have a nominal strength to resist the lesser of the amplified seismic load or the maximum force the system can deliver.

- It is acceptable to use the capacity listed for the thickest single member or back-to-back members for thicker stud members in the same configuration. Stud design by specifier.

- See Fastening Systems for more information on Simpson Strong-Tie fasteners.

Code Reports & Compliance

Drawings

| DWG | DXF | RFA | IFC | SAT | |||

|---|---|---|---|---|---|---|---|